rice Z type bucket conveyor

Tuesday November-04 2025 17:31:19

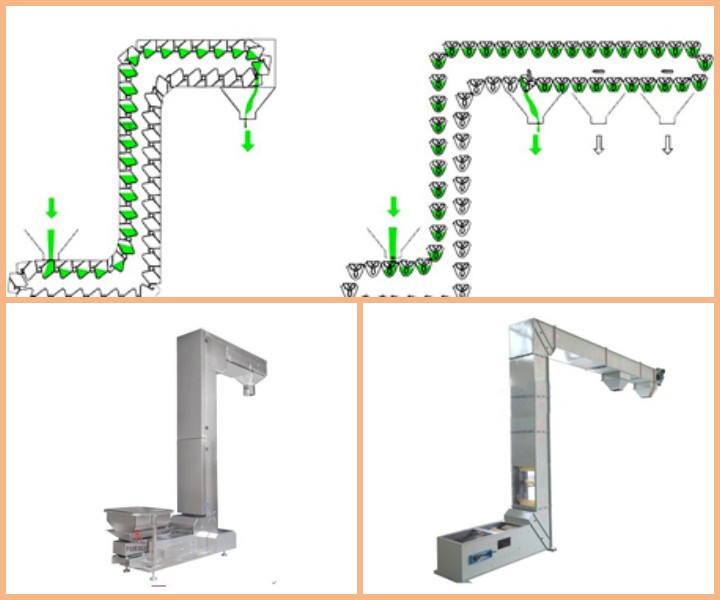

The Rice Z type Bucket Conveyor is a type of elevator that uses a combination of horizontal-vertical-horizontal conveying methods to lift rice. It uses a chain to drive the buckets, gently lifting the rice from a low position to a high position. This allows for the transfer of rice between storage, cleaning, and processing stages in rice production and processing. The lifting height ranges from 3 to 30 meters, and the conveying capacity is 5-50 m³/hour. Bucket capacities of 1L, 2L, 3L, 4L, 5L, and 6L are available depending on the conveying capacity. The material is 304 or 316L stainless steel, ensuring cleanliness and hygiene, and meeting food hygiene standards for rice production.

Rice is easily broken during transportation, contaminated by air, and prone to dampness and mold. The rice Z type bucket conveyor uses a sealed structure to prevent dust contamination and moisture. The hopper operates at a low speed and smoothly to reduce collisions and friction between materials, thereby reducing the breakage rate of rice and ensuring the integrity of rice grains. Depending on the rice processing scenario, 2-7 feed inlets and outlets can be added.

Rice Z type bucket conveyor video

What is the use of rice Z type bucket conveyor?

The rice Z type bucket conveyor can be used in rice processing, storage, and packaging production scenarios to vertically lift rice and similar bulk materials such as husks and broken rice from one level to another.

In rice processing production lines, the rice Z type bucket conveyor is used to transport raw paddy from the raw material silo to processing stages such as cleaning equipment and rice hullers, or to transfer processed brown rice and polished rice to subsequent color sorting, polishing, and grading equipment, facilitating seamless rice processing between stages.

In finished/semi-finished rice lifting and storage, processed finished rice is vertically lifted into the finished product silo for storage using the rice Z type bucket conveyor; it can also transport rice stored in the silo to the hopper above the packaging machine to supply materials for the packaging process, reducing manual handling.

Byproducts such as husks and broken rice generated during rice processing can be transported by the rice Z type bucket conveyor to designated collection silos or processing equipment, such as husk incinerators or broken rice reprocessing equipment, achieving centralized recycling and reuse of byproducts.

What are the advantages of rice Z type bucket conveyor?

The rice Z type bucket conveyor features a Z-shaped structure and a horizontal + vertical conveying method, making it suitable even in confined spaces, such as grain silos and processing workshops. It employs inflow feeding and a stable low-speed operation of 0.18 m/s, quickly tumbling and unloading to prevent rice collisions and breakage, with a broken rice rate of <0.5%. The fully enclosed casing allows for the addition of a pulse dust collector for dusty rice, directly purifying the dust generated during conveying and preventing rice contamination. A frequency converter can also be installed to adjust the speed according to the operating speed of the receiving equipment.

How does the rice Z type bucket conveyor work?

The working principle of the rice Z type bucket conveyor is relatively simple and efficient. The rice enters the feed hopper through the feed port, and then the bucket-shaped hopper transfers the rice to the chain. The movement of the chain transports the rice to the target location along the set path. During the transportation process, rice is not easy to accumulate and get stuck, ensuring the continuity and stability of transportation.

Rice Z type bucket conveyor parameters

| Model | ZD-160 | ZD-250 | ZD-330 | ZD-400 | ZD-500 | ZD-530 | ZD-650 | ZD-800 |

| Capacity(m3/h) | 2.9-4.8 | 4.6-15.7 | 6.0-10.0 | 15.2-25.2 | 25.4-42.3 | 20-33.4 | 32.9-54.9 | 40.6-67.6 |

Rice Z type bucket conveyor customer case

| Application Scenario | Lifting Height (m) | Horizontal Conveying Distance (m) | Lifting Capacity (t/h) | Motor Power (kW) | Key Configurations | Special Requirements |

| Rice Processing Plant | 10.5 | Upper 3.2 / Lower 2.8 | 12 | 5.5 | 304 stainless steel hopper/dustproof housing | Food-grade lubricating oil system |

| Grain storage | 15.2 | Upper end 4.5/Lower end 3.8 | 25 | 11 | Reinforced chain/Explosion-proof motor | Equipped with intelligent material level control system |

| Rice noodle raw material pre-processing workshop | 8.0 | Upper end 2.5/Lower end 2.0 | 8 | 3.7 | Food-grade PP plastic bucket/Variable frequency speed control | Anti-static treatment |

Rice Z type Bucket Conveyor Manufacturer

Dahan Rice Z type Bucket Conveyor is a manufacturer with 15 years of experience in rice conveying. We produce Z type bucket conveyors, multi-point feeding types, and mobile types for transporting rice. In addition to the Z-type, we also offer C-type, E-type, F-type, and T-type conveyors to suit various rice transportation scenarios. Depending on the characteristics of the rice being transported, such as particle size, moisture content, and dust content, we also provide customized products, such as those equipped with dust collection devices, explosion-proof designs, and variable frequency motors.

Rice Z type bucket conveyor FAQ

What types of rice are suitable for Z type bucket conveyor?

It can convey granular rice such as brown rice, polished rice, glutinous rice, broken rice, black rice, and by-products of rice processing such as rice husk powder.

Is rice Z type bucket conveyor equipment maintenance complicated?

The modular structure design, inspection door and observation window facilitate quick troubleshooting, and daily maintenance only requires lubricating the chain and checking the hopper wear every quarter.

What equipment can the Rice Z type bucket conveyor be used with?

The Rice Z type bucket conveyor can transport rice to a screening machine to remove impurities and sort it into different sizes; it can also transport rice to a packaging machine to package it into finished products. Furthermore, it can be used in conjunction with rice hullers, rice milling machines, color sorters, polishing machines, etc.

Recommend Product

- Bucket Elevator for Rice

- Food Grade Bucket Elevator

- Z Type Bucket Conveyor

- Stainless Steel Bucket Elevator