Z Type Bucket Conveyor

It can transport various bulk materials in a horizontal-vertical-horizontal combination, with low material breakage rate, no material spillage and no dust pollution.

| Discharging height | 1.5-30m |

| Feeding length | ≤1.3m |

| Discharging length | ≤1.3m |

| Hopper capacity | 1L, 1.8L, 3.8L and 6.5L |

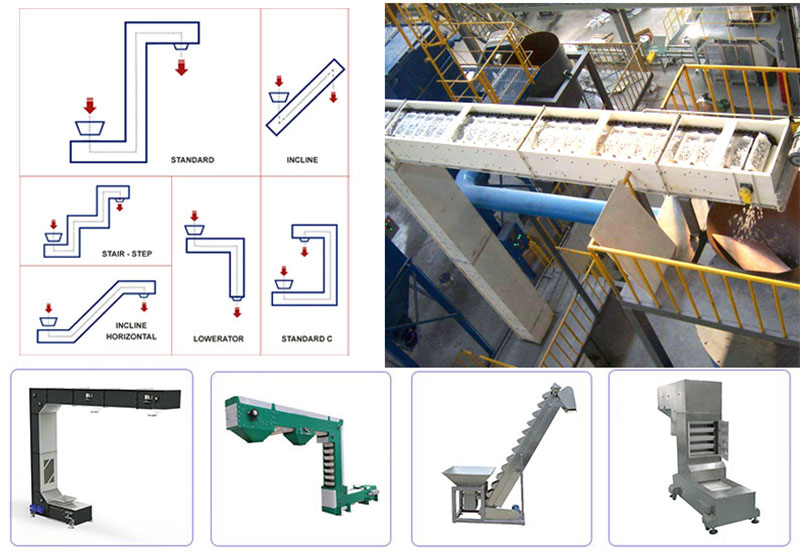

| Machine type | Z type, C type and multiple discharge ports |

What is a Z Type Bucket Conveyor?

The Z Type Bucket Conveyor adopts a unique "horizontal-vertical-horizontal" running track to form the shape of the letter "Z", which perfectly solves the multi-directional conveying needs that traditional vertical bucket elevators cannot achieve. The equipment completes material lifting and turning through a chain or belt-driven bucket in a closed casing, which is particularly suitable for industrial scenarios where space is limited but complex path conveying is required.

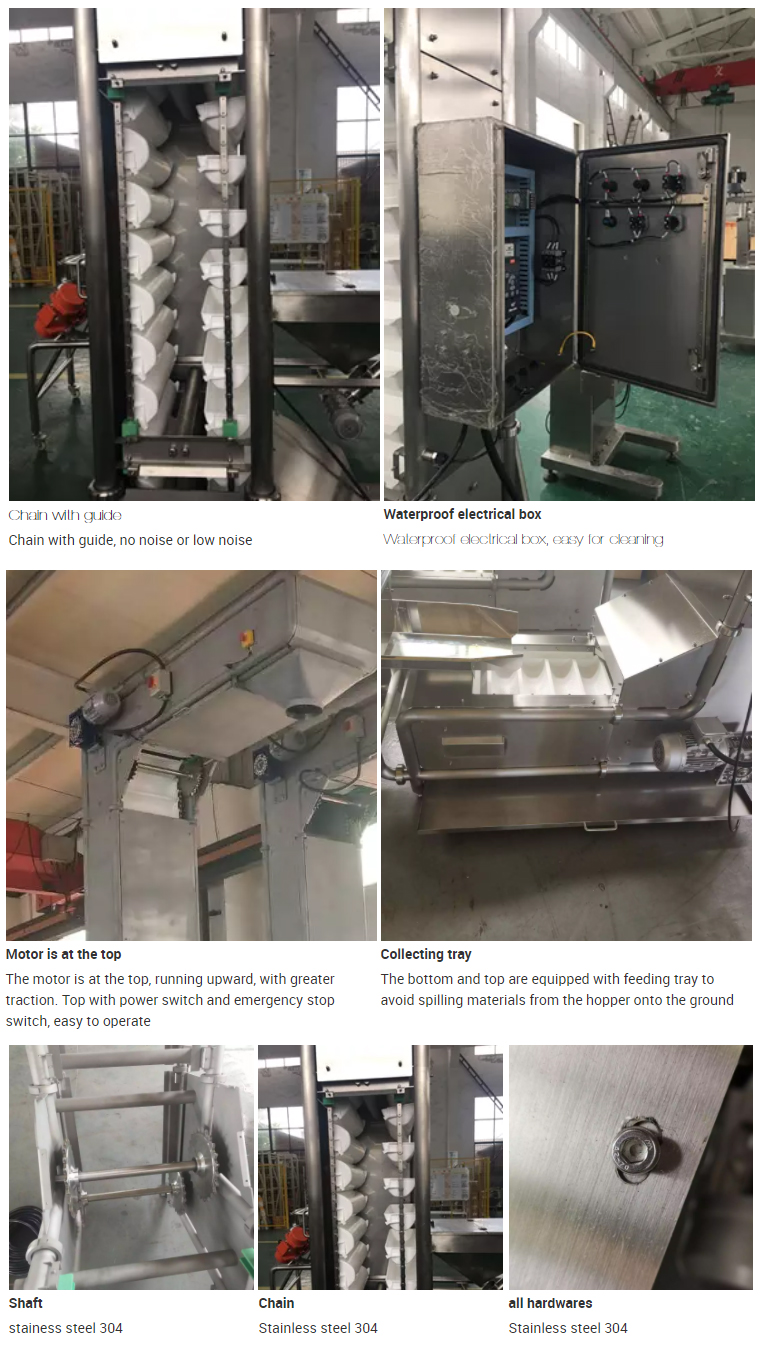

Dahan Z Type Bucket Conveyor is made of food-grade 304/316L stainless steel or carbon steel sprayed plastic, equipped with wear-resistant chains and customized hoppers to ensure safe and reliable operation of the equipment in food processing, chemical raw materials, pharmaceutical preparations and other fields. Our Z Type Bucket Conveyor supports:

Single-point or multi-point feeding/unloading design

Adjustable conveying capacity from 2.9m³/h to 54.9m³/h

Lifting height up to 15 meters (special design up to 50 meters)

Applicable temperature range -10℃ to 120℃

What is the difference between Z Type Bucket Conveyor and traditional elevator?

| Comparison Dimensions | Z type Bucket Elevator | Traditional Bucket Elevator |

| Pictures |

|

|

| Conveying Path | Horizontal-vertical-horizontal combined conveying (Z-shaped) | Vertical conveying only |

| Space utilization | Can be installed against the wall, saving 30%-50% space | Requires independent vertical space |

| Flexibility of feeding and discharging | Supports multi-point feeding and unloading | Usually single-point feeding and unloading |

| Material adaptability | More suitable for fragile and low-abrasive materials | Can handle highly abrasive materials |

| Crushing rate | <1% (inflow feeding) | 3%-8% (extract feeding) |

| Sealing | Fully enclosed design, dust leakage <0.1% | Partially open design, easy to generate dust |

| Easy to maintain | Modular design, quick hopper replacement | Requires shutdown to disassemble the shell for maintenance |

| Typical applications | Food, medicine, fine chemicals | Mining, cement, bulk materials |

What types of Z Type Bucket Conveyor are there?

Z type bucket elevator can be classified into chain drive and belt drive by driving mode, and the materials include stainless steel, carbon steel and plastic.

Classification by driving mode: chain drive type (using stainless steel ring chain, strong bearing capacity, suitable for heavier materials, such as hardware, mineral particles); belt drive type (food grade rubber belt, smooth operation, suitable for fragile materials, such as potato chips, pills).

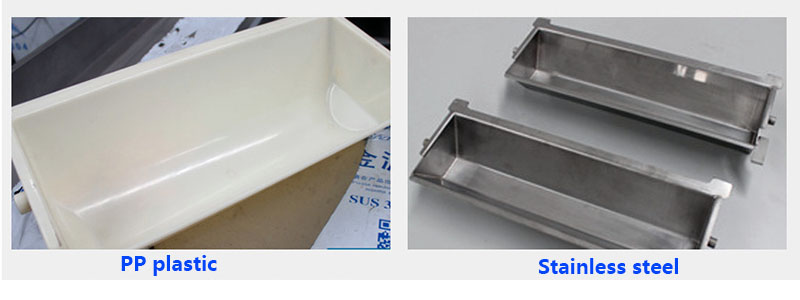

Classification by material: all stainless steel type (304/316L, food and medical grade, corrosion resistant);Carbon steel spray type (economical and practical, the first choice for chemical metallurgical industry), PP plastic hopper type (non-toxic treatment, food grade certification).

What are the advantages of Z Type Bucket Conveyor?

Low crushing rate design: using inflow feeding and induced unloading technology, the material slides naturally into the hopper from the feed port, avoiding the extrusion and damage caused by the traditional digging method, which is particularly suitable for the complete transportation of fragile materials such as potato chips, pills, and puffed foods.

Ultimate space optimization: through the Z-shaped path design, the equipment can achieve corner transportation without additional transfer points, saving more than 40% of floor space compared to traditional designs.

Environmental protection and energy saving: the sealing performance reaches 99.5%, the dust escape amount is <5mg/m³, which saves 15%-30% energy compared to traditional elevators (no return material phenomenon), the noise is <65dB, and it meets ISO 4871 standards

Sealed operation without pollution: the entire machine housing is sealed, there is no leakage during operation, and no dust flying

Z Type Bucket Conveyor Parameters

| Model | ZD-160 | ZD-250 | ZD-330 | ZD-400 | ZD-500 | ZD-530 | ZD-650 | ZD-800 |

| Capacity(m3/h) | 2.9-4.8 | 4.6-15.7 | 6.0-10.0 | 15.2-25.2 | 25.4-42.3 | 20-33.4 | 32.9-54.9 | 40.6-67.6 |

What are the applications of Z Type Bucket Conveyor?

Z Type Bucket Conveyor can be used in the food industry to transport biscuits, gummy candies, marshmallows, steamed buns, pancakes, chicken essence, milk tea, jelly, shrimp crackers, potato chips, rice noodles, glutinous rice balls, dumplings, chocolate, peanuts, coffee, sugar, nuts, sugar beans, melon seeds, pistachios, walnuts, almonds, rice, millet and other granular and powdered foods; the chemical industry to transport plastic granules, powder (PP PE PS), activated carbon, preservatives, additives, fertilizers, etc.; the pharmaceutical industry to transport tablets, capsules, granular drugs, etc.; the hardware industry to transport screws, nuts, metal accessories, etc.

Z Type Bucket Conveyor Options

Traction system: stainless steel chain/food grade belt, optional automatic tensioning device

Hopper assembly: PP/stainless steel material, special streamlined design to prevent material jamming

Drive unit: SEW/Siemens reduction motor, IP55 protection grade

Housing structure: segmented flange connection, with silicone sealing strip in the middle

Safety device: overload protection, emergency stop switch, anti-reverse brake

What are the common problems with Z Type Bucket Conveyor?

Q: What is the maximum tilt angle of Z Type Bucket Conveyor?

A: The vertical section of the standard model is 90°, and the tilt section can be adjusted between 45°-75°3

Q: How to handle sticky materials?

A: Vibrator + Teflon coated hopper can be configured, or a large tilt angle design can be selected8

Q: Equipment maintenance cycle?

A: Daily only monthly lubrication of the chain and annual comprehensive inspection (remote diagnosis service is provided)6

Q: What are the advantages compared with tube chain conveyors?

A: Higher conveying capacity (up to 67m³/h), lower energy consumption (no compressed air required)

Stainless Steel Bucket Elevator

Stainless Steel Bucket Elevator