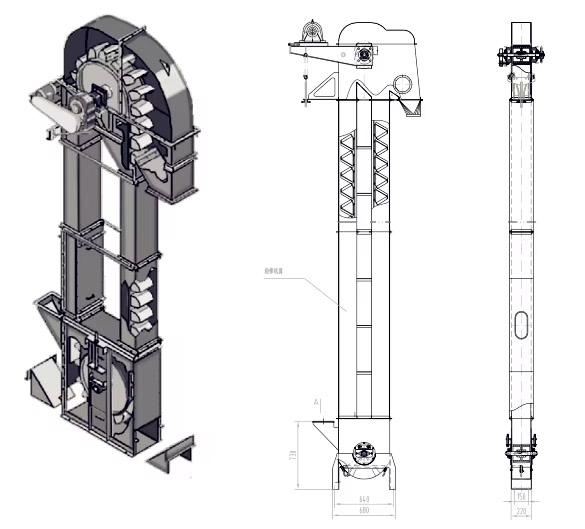

Wood Chip Conveying Bucket Elevator

Mechanical equipment for conveying wood chips vertically or at an angle

Conveying capacity: Typically 10-500 tons/hour

Lifting height: Up to 30 meters or more

Motor power: 5.5-75kW

Hopper capacity: 0.5-20 liters

What is Wood Chip Conveying Bucket Elevator?

Wood Chip Conveying Bucket Elevator is a device specially used for conveying wood chips vertically or obliquely. It lifts wood chips from low to high through a bucket fixed on a belt or chain, and is widely used in papermaking, biomass energy and other industries.

What are the uses of Wood Chip Conveying Bucket Elevator?

Efficient conveying: realize large-scale and continuous vertical conveying of wood chips to improve production efficiency.

-Space saving: reduce floor space and optimize factory layout through vertical lifting.

Protect materials: reduce the breakage and dust generation of wood chips during transportation to ensure material integrity.

What are the applications of Wood Chip Conveying Bucket Elevator?

Papermaking industry: used to convey papermaking raw materials (such as albizzia wood chips) to the production line.

- Biomass energy: convey wood chips to biomass power generation equipment.

- Wood processing: used for lifting and conveying materials such as wood chips and sawdust.

How does wood chip conveying bucket elevator work?

The wood chips enter the hopper through the feed port, and the hopper moves upward driven by the traction chain. When it reaches the top, the wood chips are discharged from the hopper under the action of gravity or centrifugal force.

Wood Chip Conveying Bucket Elevator Parameters

| Capacity | 10 - 500 m³/h (depending on model and bucket capacity) |

| Lifting Height | 3 - 50 m (customizable) |

| Bucket Width | 200 - 800 mm |

| Bucket Spacing | 200 - 500 mm |

| Bucket Volume | 1 - 20 L |

| Conveying Speed | 0.5 - 3 m/s |

| Motor Power | 2 - 75 kW (depending on conveying height and load) |

| Density of conveying material | 200 - 800 kg/m³ (for light materials such as wood chips) |

| Improvement method | Chain, belt or plate chain |

| Import and export of materials | Inlet: bottom feed, discharge: top discharge |

| Material | Carbon steel, stainless steel, wear-resistant steel (depending on application requirements) |

What are the advantages of wood chip conveying bucket elevator?

- High efficiency and stability: High-strength materials are used to ensure long-term stable operation.

- Low maintenance: Simple structure, easy to maintain and clean.

- Environmental protection and energy saving: The closed design reduces dust leakage and reduces energy consumption.

What are the structural components of wood chip conveying bucket elevator?

The main structures of Wood Chip Conveying Bucket Elevator include:

- Hopper: used to carry wood chips, mostly made of wear-resistant steel plates.

- Belt/chain: used to connect and drive the hopper.

- Driving device: including motor, reducer and transmission wheel.

- Casing: closed design to prevent dust from spilling.

Wood Chip Conveying Bucket Elevator Customer Cases

| Application | Lifting Height | Capacity |

| Vertical transport of wood chips for biomass fuel feeding into boilers. | 25–30 meters (to feed into high-level storage silos). | 50–100 m³/h (continuous operation for large-scale power plants) |

| Moving wood chips from sawmill floor to storage or processing units. | 10–15 meters (typical for factory layouts). | 20–40 m³/h (matches mid-sized sawmill output). |

| Elevating wood chips to pellet press hoppers. | 8–12 meters (optimized for compact factory setups). | 15–30 m³/h (matches pellet press demand). |

| Loading wood chips from ground level onto ships or trucks. | 18–22 meters (sufficient for vessel loading). | 80–120 m³/h (high throughput for export operations). |

How to choose a Wood Chip Conveying Bucket Elevator

When choosing a Wood Chip Conveying Bucket Elevator, the following factors should be considered:

- Material characteristics: such as the size, moisture and density of the wood chips.

- Conveying capacity: select the appropriate conveying capacity according to production needs.

- Lifting height: ensure that the equipment can meet the vertical conveying requirements.

- Equipment material: select wear-resistant and corrosion-resistant materials to extend service life.

Wood chip conveyor bucket elevator for sale

Entry-level models: 1,000–1,000–5,000 (small capacity, low lift height, carbon steel construction)

Mid-range models: 5,000–5,000–20,000 (medium capacity, moderate lift height, stainless steel or wear-resistant components)

High-end models: 20,000–20,000–75,000+ (large capacity, high lift height, custom designs, corrosion-resistant alloys)

Note: Prices are approximate and depend on manufacturer, region, and additional features.

(1) Model & Capacity

Small models (e.g., TD160, NE15): Capacity: 5–20 m³/h; Price: 1,000–1,000–5,000

Medium models (e.g., NE50, TD400): Capacity: 30–100 m³/h; Price: 5,000–5,000–20,000

Large models (e.g., NE800, TD630): Capacity: 100–800 m³/h; Price: 20,000–20,000–75,000+

(2) Lifting Height

Low height (4–10m): 1,000–1,000–8,000

Medium height (10–30m): 8,000–8,000–25,000

High height (30–40m+): 25,000–25,000–75,000+

(3) Material & Durability

Carbon steel: Cheaper (1,000–1,000–15,000) but less durable for abrasive wood chips.

Stainless steel: Better corrosion resistance (5,000–5,000–30,000).

Wear-resistant alloys (e.g., AR steel liners): Best for long-term use (15,000–15,000–75,000+) .

(4) Additional Features

Dust-proof sealing: +1,000–1,000–5,000

Variable speed control: +2,000–2,000–8,000

Custom hopper designs: +1,500–1,500–10,000

Biomass pellet bucket elevator

Biomass pellet bucket elevator Chemical Raw Material Bucket Elevator

Chemical Raw Material Bucket Elevator