What is the difference between belt conveyor and bucket elevator?

Monday February-10 2025 16:45:58

Belt Conveyor and Bucket Elevator are both common material conveying equipment, but they have significant differences in many aspects.

1. Working Principle

Belt Conveyor conveys materials through a continuously running conveyor belt. The materials are placed on the conveyor belt and are transported from one place to another as the conveyor belt moves. It is suitable for horizontal or small-angle material transportation.

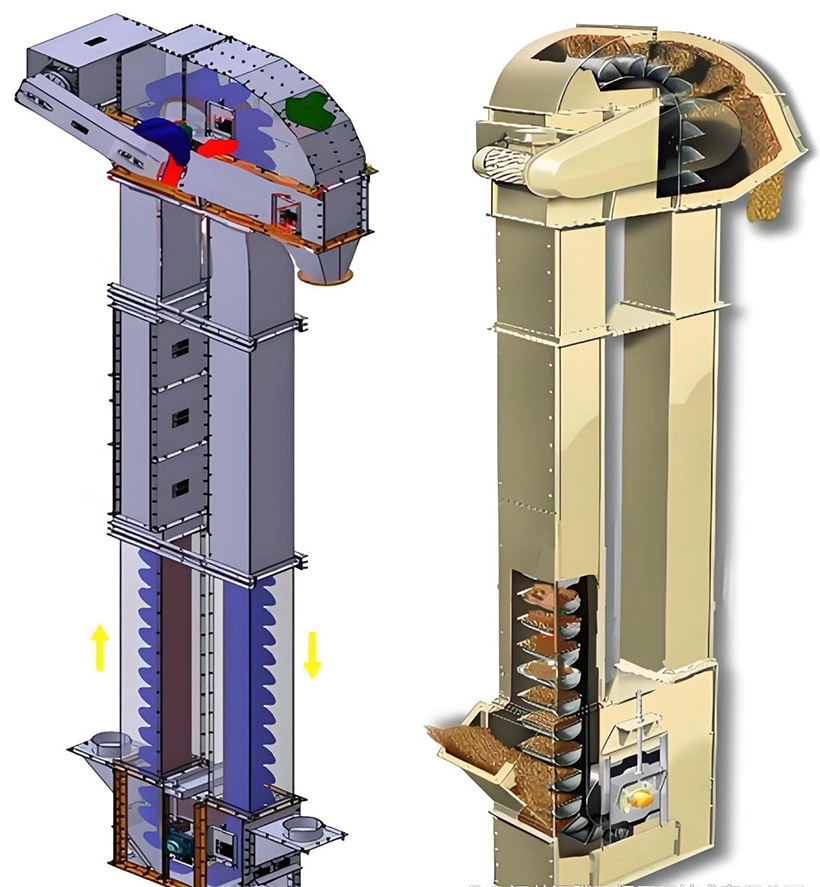

In contrast, Bucket Elevator mainly relies on the hopper to load and unload materials, and realizes the vertical lifting of materials through the continuous movement of chains or belts. Its working principle is similar to that of a continuous bucket elevator, which is suitable for occasions where materials need to be lifted from low to high.

2. Scope of Application

Belt Conveyor is more suitable for horizontal or short-distance inclined transportation of various bulk materials and finished objects, such as coal, gravel, sand, cement, fertilizer, grain, etc. It has a simple structure, is easy to use and easy to maintain, and is widely used in mining, ports, metallurgy, electricity, chemical industry and other fields.

Bucket Elevator is mainly used for vertically lifting powdery, granular and small block materials, such as coal, cement, stone, etc., and is widely used in building materials, metallurgy, chemical industry and other industries. Due to its vertical lifting characteristics, Bucket Elevator has significant advantages in saving space and improving efficiency.

3. Structural characteristics

The structure of Belt Conveyor is relatively simple, mainly composed of conveyor belt, drive device, roller, roller, tensioning device, cleaning device and other parts. The conveyor belt moves according to the principle of friction transmission, and has the characteristics of large conveying capacity, long conveying distance and stable conveying.

Bucket Elevator is mainly composed of drive device, upper section, middle casing, lower section, traction parts (bucket belt or plate chain), hopper and tensioning device. It has a compact structure and small footprint, and can be easily connected with other conveying equipment to form a continuous conveying system.

4. Maintenance

The maintenance of Belt Conveyor is mainly concentrated on key components such as conveyor belt, roller, bearing, etc. It is necessary to regularly check the wear and aging of the conveyor belt and replace the damaged or aged conveyor belt in time. At the same time, it is also necessary to regularly lubricate and inspect the rollers and bearings to ensure their normal operation.

Bucket Elevator needs to regularly check the wear of the hopper, chain or belt during use, and replace damaged parts in time to ensure the normal operation of the equipment. In addition, it is necessary to regularly clean the debris and dust inside the equipment to keep the equipment clean and hygienic.