What is a bucket elevator?

Monday February-10 2025 15:58:34

Bucket elevator is a kind of mechanical equipment commonly used for vertical conveying of granular and small block materials. It consists of motor, reducer, upper and lower end bearings, casing, bucket side roller, through-flow bucket and other parts. When working, the bucket elevator drives the through-flow bucket to circulate and lift the materials through the transmission of the bucket side roller to complete the continuous conveying of materials.

2. Features of bucket elevator

1. Simple structure, small size, light weight, easy assembly and maintenance;

2. Large conveying capacity, fast speed and high conveying height;

3. The lifted materials are not easy to be damaged and less polluted;

4. Sealed conveying can be carried out to reduce environmental pollution and ensure the cleanliness of the production environment;

5. Strong adaptability and can be used in air conveying systems of various materials.

3. Application industries of bucket elevator

Bucket elevator is widely used in building materials, chemical industry, metallurgy, electric power, coal and other industries, and plays a very important role in the conveying of powdered or small block materials such as cement, sand and gravel, ceramics, pigments, fertilizers, calcium carbonate, manganese ore, etc.

4. Bucket Elevator Customer Cases

A cement plant purchased a bucket elevator produced by our company to transport raw materials in the cement production process. The equipment has high conveying efficiency, low noise and small footprint, which greatly improves the efficiency, quality and safety of cement production.

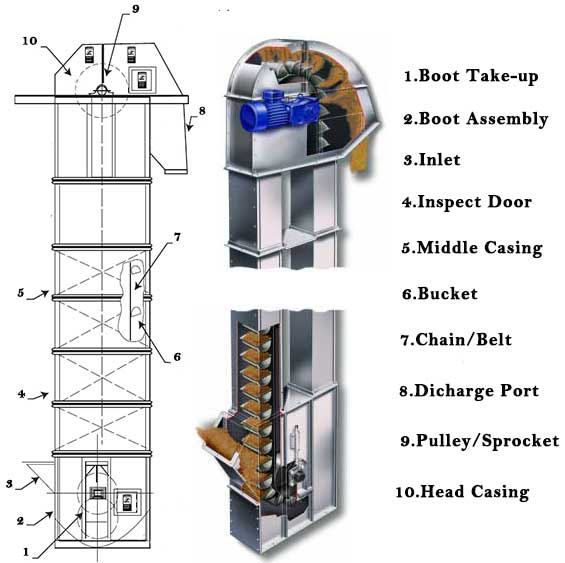

5. Bucket Elevator Structure

The bucket elevator is mainly composed of the following parts:

1. Motor: provides driving force;

2. Reducer: reduces the output speed of the motor;

3. Upper and lower end bearings: support the elevator shaft;

4. Casing: fix the entire equipment;

5. Bucket side roller: receives the through-flow bucket and drives the through-flow bucket to lift;

6. Through-flow bucket: used to lift materials.

6. Working principle of bucket elevator

The bucket elevator uses the weight of the through-flow bucket to make the material transfer from bottom to top along the elevator bucket, and finally dump it into the required position to complete the material transportation. In actual work, the bucket elevator can control the direction of transportation by controlling the forward and reverse rotation of the motor.

7. Bucket Elevator Model Specifications

Common bucket elevators have different models and specifications to meet different material transportation needs. Usually, the appropriate equipment model and specifications are selected according to parameters such as material conveying capacity, lifting height, conveying speed and motor power.

TD bucket elevator: rated conveying capacity range 0.5~61m³/h, lifting height range 3~40m, maximum conveying particle size not exceeding 25mm.

H bucket elevator: rated conveying capacity range 4.5~238m³/h, lifting height range 4~40m, maximum conveying particle size not exceeding 25mm.

NE bucket elevator: rated conveying capacity range 10~1100m³/h, unlimited lifting height range, suitable for conveying granular and powdery materials, especially for conveying sticky materials.

HL bucket elevator: rated conveying capacity range 15~700m³/h, unlimited lifting height range, suitable for conveying granular and powdery materials.

D bucket elevator: rated conveying capacity range 60~600m³/h, unlimited lifting height range, suitable for conveying granular and powdery materials.

TB type bucket elevator: rated conveying capacity range 50~400m³/h, unlimited lifting height range, suitable for conveying granular and powdery materials.

8. Bucket elevator installation method

When installing a bucket elevator, you need to use special lifting equipment to lift the elevator to the designated location. During installation, the elevator frame should be horizontal and the shaft should be vertical. Under the premise of ensuring safety, the foundation should be fixed, wired, and tested to ensure the safe and stable operation of the elevator.

In short, the bucket elevator is a device that can effectively and quickly transport materials and is widely used in production in various fields. It is popular among users because of its simple structure, strong adaptability, and convenient use.