What is a Z Type Bucket Elevator?

Thursday March-20 2025 15:56:36

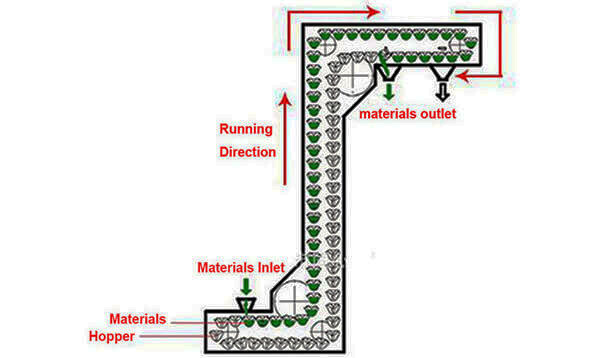

Z Type Bucket Elevator is a specialized material handling equipment designed for vertical and horizontal transportation of bulk materials, such as grains, powders, granules, and other dry products. It is named "Z-Type" due to its unique Z-shaped configuration, which allows it to efficiently move materials both vertically and horizontally in a single system. This design makes it ideal for facilities with space constraints or complex layout requirements.

Features of a Z Type Bucket Elevator

Z Shaped Design: Combines vertical and horizontal conveying in one system, saving space.

Gentle Handling: Minimizes product damage, making it suitable for fragile materials.

High Efficiency: Continuous operation with minimal energy consumption.

Versatility: Can handle a wide range of materials, including grains, powders, and granules.

Hygienic Construction: Often made of stainless steel for food-grade applications.

Customizable: Can be tailored to specific material types, capacities, and facility layouts.

Z Type Bucket Elevator Application

Food Industry: Transporting flour, sugar, grains, and other food products.

Agriculture: Moving seeds, fertilizers, and animal feed.

Chemical Industry: Handling powders, granules, and other bulk chemicals.

Pharmaceuticals: Transporting raw materials and finished products.

Construction: Conveying cement, sand, and other building materials.

How Does a Z Type Bucket Elevator Work?

Loading: Material is fed into the elevator's boot (bottom section) through an inlet.

Vertical Lifting: Buckets attached to a belt or chain scoop up the material and carry it vertically.

Horizontal Transfer: At the top, the buckets move horizontally to discharge the material.

Discharge: Material is released into a chute or conveyor for further processing.

Return: Empty buckets return to the boot to repeat the cycle.

Structure of Z Type Bucket Elevator

Boot Section: Where material is loaded into the buckets.

Vertical Section: Lifts material to the desired height.

Horizontal Section: Transports material horizontally before discharge.

Head Section: Where material is discharged.

Buckets: Attached to a belt or chain, designed to carry material.

Drive System: Includes motor, gearbox, and pulleys to power the elevator.

Casing: Encloses the system to prevent dust and spillage.

Z Type Bucket Elevator Parameter

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

Z Type Bucket Elevator Customer Case

Food Processing Plant: Transporting flour and sugar between production stages.

Challenge: Needed a compact and efficient system to move materials vertically and horizontally in a limited space.

Solution: Installed a stainless steel Z-Type Bucket Elevator with food-grade buckets and a gentle discharge mechanism.

Results:

Increased production efficiency by 25%.

Reduced product damage and waste.

Met all food safety and hygiene standards.

Z Type Bucket Elevator is a versatile and efficient solution for handling bulk materials in industries with space constraints or complex layout requirements. Its unique Z-shaped design allows for both vertical and horizontal transportation, making it ideal for food, agriculture, chemical, and pharmaceutical applications. When selecting a Z-Type Bucket Elevator, consider factors like capacity, lift height, and material type to ensure it meets your specific needs.

Recommend Product

- Sugar Bucket Elevator

- Stainless Steel Bucket Elevator

- Plastic granule bucket elevator

- Bucket Elevator With Hopper Feeder