Vertical Chain Elevator

A device that uses chain drive to lift materials vertically or obliquely from a low place to a high place.

| Lifting height | usually 5-50 meters |

| Conveying capacity | 10-500 tons/hour |

| Motor power | 5-50kW |

| Material | carbon steel, stainless steel, etc. |

What is Vertical Chain Elevator?

Vertical Chain Elevator is a device used to transport materials in a vertical or inclined direction. It is widely used in chemical, food, building materials, metallurgy and other industries. It lifts materials from low to high through a combination of chains and hoppers. It is suitable for efficient transportation of various materials such as powder, granules, and blocks.

What are the advantages of Vertical Chain Elevator?

Heavy-duty construction: With strong chains and wear-resistant buckets, it can handle bulk materials such as grains, cement, minerals and chemicals.

Efficient conveying: It can continuously and stably lift large amounts of materials with a conveying capacity of up to 200 tons/hour.

Minimized product damage: Unlike screw conveyors, chain elevators prevent fragile materials (e.g. food particles, pharmaceuticals) from being crushed or deteriorated, and prevent blockages.

Small footprint: Ideal for facilities with limited floor space - materials can be transported vertically without tilting the conveyor.

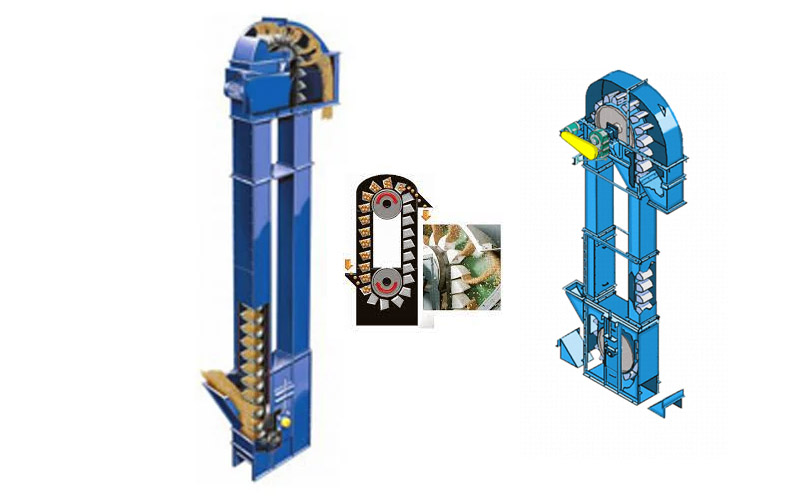

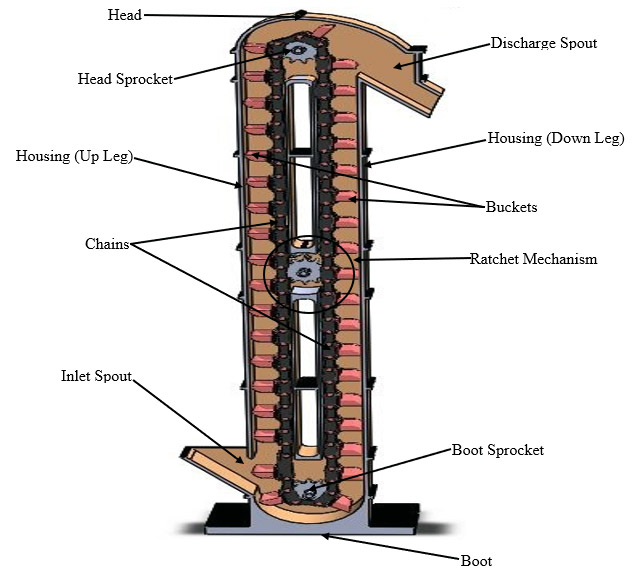

How does Vertical Chain Elevator work?

Vertical Chain Elevator drives the chain to move through a motor, and a hopper is installed on the chain. The material enters the hopper from the bottom feed port, is brought to the top as the chain is lifted, and then is discharged from the discharge port under the action of gravity or centrifugal force. The whole process is carried out continuously to achieve vertical transportation of materials.

Vertical Chain Elevator Technical Parameters

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

What are the structures of Vertical Chain Elevator?

Drive device: includes motor and reducer to provide power.

Chain and hopper: The chain drives the hopper to move, and the hopper is used to carry materials.

Shell: Closed structure to prevent material leakage and dust diffusion.

Feed port and discharge port: used for material entry and discharge respectively.

Tensioning device: used to adjust the tightness of the chain to ensure smooth operation.

What industries can Vertical Chain Elevator be used for?

Chemical industry: used for conveying fertilizers, plastic particles, etc.

Food industry: suitable for conveying food raw materials such as flour, sugar, and grains.

Building materials industry: used for lifting materials such as cement, lime, sand and gravel.

Metallurgical industry: conveying ore, coal, etc.

Environmental protection industry: used for garbage disposal, sludge transportation, etc.

Vertical Chain Elevator customer cases

| Application scenario | Lift height | Lift capacity | Motor power | Customer feedback |

| Vietnam Cement Plant – transporting cement clinker from the kiln to the cooling system. | 25 meters | 150 tons/hour | 30 kW | Reliable high temperature operation - withstands temperatures over 200°C without deformation. |

| USA food processing – lifting grain to storage silos without damage | 15 meters | 50 tons/hour | 11 kW | Zero grain damage – smooth operation, maintaining grain quality; easy to clean – hygienic design meets food safety standards. |

| Russian mining plant – lifting ore from underground to processing line. | 40m | 300t/hr | 55KW | High uptime – rugged construction withstands extreme loads while minimizing wear; Higher throughput – processes ore 20% faster. |

How to select a Vertical Chain Elevator?

1. Material properties

The physical and chemical properties of the material are the primary considerations for selection, mainly including:

Material type: powder, granular, block or mixed material.

Density: The density of the material affects the load and motor power selection of the elevator.

Flowability: Materials with poor flowability (such as sticky materials) require specially designed hoppers and unloading methods.

Corrosiveness: Corrosive materials (such as fertilizers and chemicals) require corrosion-resistant materials (such as stainless steel).

Temperature: High-temperature materials (such as hot cement) require high-temperature resistant chains and hoppers.

Abrasiveness: Materials with strong abrasiveness (such as ore, sand and gravel) require wear-resistant materials (such as high manganese steel).

2. Lifting height

The lifting height directly affects the structural design and motor power of the equipment:

Low height (5-15 meters): suitable for small production lines or places with limited space.

Medium height (15-30 meters): suitable for most industrial applications, such as building materials and chemical industries.

High height (above 30 meters): requires customized design to ensure chain strength and equipment stability.

3. Lifting capacity

The lifting capacity (conveying capacity) is the core parameter of the selection, usually in tons/hour (t/h):

Small lifting capacity (<50 t/h): suitable for small production lines or intermittent production.

Medium lifting capacity (50-200 t/h): suitable for medium-sized production lines, such as food and chemical industries.

Large lifting capacity (>200 t/h): suitable for large production lines, such as cement and metallurgical industries.

The calculation of lifting capacity needs to be combined with material density and hopper capacity to ensure that the equipment can meet production needs.

4. Material selection

Material selection directly affects the durability and applicability of the equipment:

Carbon steel: economical and practical, suitable for conveying non-corrosive and non-food grade materials.

Stainless steel (304/316): corrosion-resistant, easy to clean, suitable for food and chemical industries.

Wear-resistant steel: suitable for conveying highly abrasive materials, such as ore and sand.

Special coating: for extreme environments (such as high temperature and strong corrosion), special coatings can be added to the surface.

5. Chain type

The chain is the core component of the Vertical Chain Elevator and needs to be selected according to the material characteristics:

Ordinary chain: suitable for light loads and non-abrasive materials.

High-strength chain: suitable for heavy loads and bulk materials.

High-temperature resistant chain: suitable for high-temperature materials.

Corrosion-resistant chain: suitable for corrosive materials.

6. Motor power

The motor power needs to be selected according to the lifting amount, lifting height and material characteristics:

Low power (<10 kW): suitable for low height and small lifting amount.

Medium power (10-30 kW): suitable for medium height and lifting amount.

High power (>30 kW): suitable for high height and large lifting amount.