Titanium dioxide conveying bucket elevator

It is a continuous conveying machine specially used for conveying powdery and granular materials such as titanium dioxide.

| Lifting height | 10-60 meters, customized according to specific needs. |

| Conveying capacity | 5-100 m³/h |

| Hopper type | Deep bucket (fine powder), shallow bucket (poor fluidity) |

| Drive power | 3-30 kW (adjusted according to height and conveying capacity) |

| Material | Carbon steel (normal), 304/316 stainless steel (highly corrosive environment) |

What is Titanium dioxide conveying bucket elevator?

Titanium dioxide conveying bucket elevator is a mechanical device specially used for vertical conveying of titanium dioxide powder or other bulk materials. It lifts the material from the bottom to the top through a series of hoppers fixed on traction members (such as belts or chains), and then discharges the material through a discharge device.

What is the purpose of Titanium Dioxide Conveying Bucket Elevator?

Vertical conveying: Efficiently lift titanium dioxide or other bulk materials from low to high.

Improve efficiency: Continuously and stably convey materials to improve production efficiency.

Reduce loss: Closed conveying reduces material loss and dust pollution during the conveying process.

What are the applications of Titanium dioxide conveying bucket elevator?

Coating industry: used to convey titanium dioxide as a pigment.

Plastic industry: used to convey titanium dioxide as a filler.

Paper industry: used to convey titanium dioxide as a coating.

Cosmetics industry: used to convey titanium dioxide as a pigment.

Food industry: used to convey titanium dioxide as a food additive.

Chemical industry: used to convey titanium dioxide raw materials and products.

Titanium dioxide conveying bucket elevator customer case

| Application scenario | Lifting capacity | Lifting height | Results |

| Titanium dioxide production line in chemical plant, used to lift raw titanium concentrate from the ground to the feed port of the reactor | 15 tons/hour/td> | 25 m | Use corrosion-resistant stainless steel bucket elevator with dust-proof sealing design to avoid material leakage. |

| The finished titanium dioxide is transported from the drying equipment to the packaging workshop and then lifted into the silo | 8 tons/hour | 12 m | Food-grade plastic hoppers are used to avoid metal contamination and are equipped with variable frequency speed regulation to adapt to different packaging speeds. |

| Ultrafine titanium dioxide powder (particle size <10μm) is lifted from the grinder outlet to the grading and screening equipment | 5 tons/hour | 8 m | Using airtight bucket elevator to prevent dust flying, in line with explosion-proof requirements |

| Large storage center, lifting bagged titanium dioxide from the bottom to the high-rise storage area | 20 tons/hour | 30 m | Equipped with a large-capacity deep bucket structure, suitable for high-intensity continuous operation, motor power 7.5kW |

A paint factory: used to convey titanium dioxide from the storage tank to the mixer, improving efficiency by 30% and reducing dust leakage by 90%.

Plastic masterbatch manufacturer: stainless steel bucket elevators are used in high-temperature workshops, which are corrosion-resistant and stable.

Multinational chemical companies: vertical conveying between production lines on multiple floors to save space.

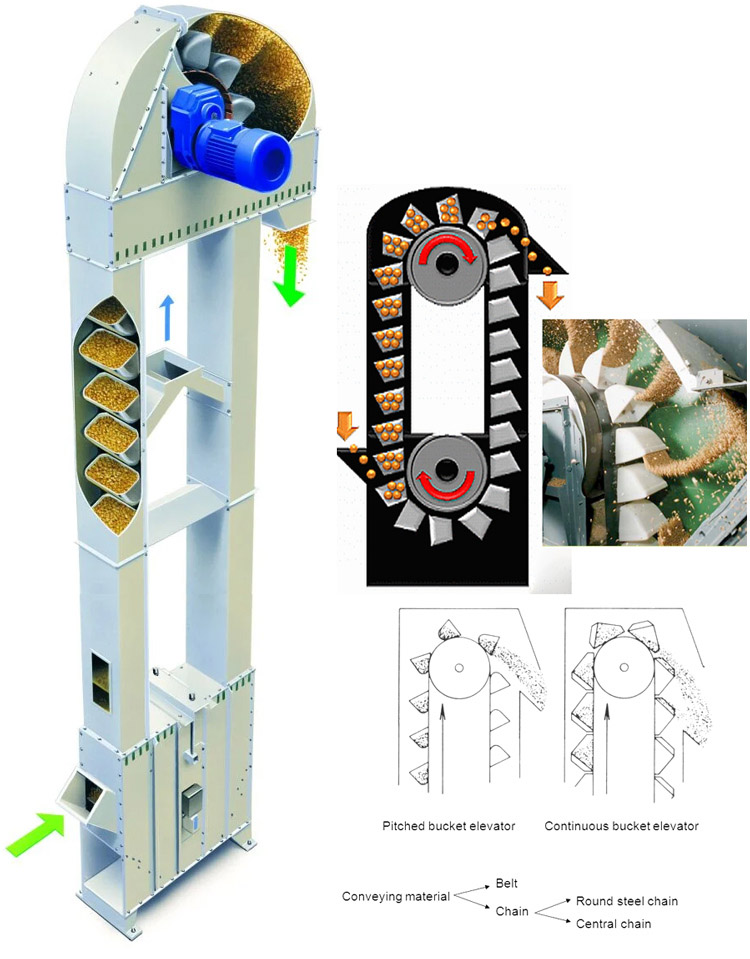

How does the Titanium dioxide conveying bucket elevator work?

Material Loading:

Titanium dioxide is fed into the buckets at the base of the elevator. This can be done using hoppers or other feeding mechanisms.

Bucket Movement:

The elevator is powered by an electric motor that drives a belt or chain. This causes the buckets, which are attached to the belt or chain, to move upward along a vertical path.

Material Transport:

As the buckets ascend, they securely hold the titanium dioxide. The design prevents spillage, ensuring efficient transport of the material.

Discharge:

Once the buckets reach the top, they tilt or open to release the titanium dioxide into a designated area, such as a storage silo or processing unit.

Return Cycle:

After discharging, the empty buckets descend back to the base, ready to be filled again, completing the cycle.

Technical parameters of Titanium dioxide conveying bucket elevator

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

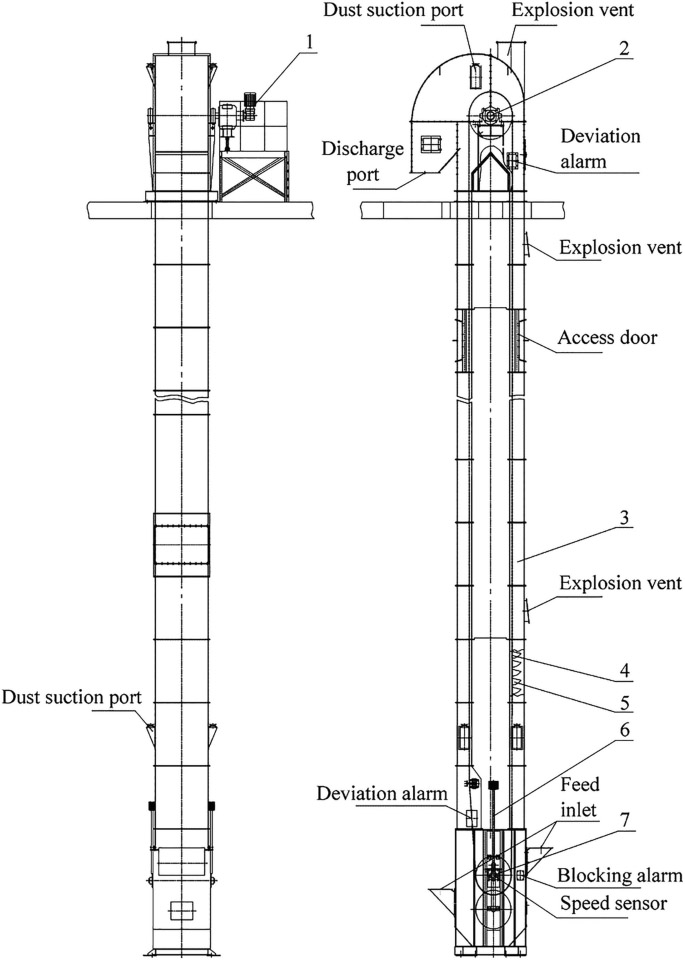

What are the structural components of Titanium dioxide conveying bucket elevator?

Traction piece: belt or chain (wear-resistant).

Hopper: fixed to the traction piece, the shape is selected according to the material characteristics.

Drive device: motor, reducer, backstop (anti-reverse).

Casing: fully enclosed structure, with observation window and inspection door.

Inlet/outlet: customizable angle and position.

Tensioning device: adjust the tension of the traction piece (bottom screw or automatic hydraulic).

Titanium dioxide conveying bucket elevator price

1. Model affects price

Light bucket elevator (TH type, TD type): suitable for small-scale titanium dioxide transportation, with a lower price of about $5,000-$15,000.

Medium bucket elevator (NE type, NSE type): suitable for medium-scale production, with a price of $15,000-$30,000.

Heavy bucket elevator (high-efficiency deep bucket type): suitable for large-scale titanium dioxide plants, with a price of $30,000-$50,000+.

2. Material affects price

Carbon steel (Q235): basic material, with a lower price of about $5,000-$20,000, suitable for general working conditions.

Stainless steel (304/316): corrosion-resistant, suitable for high-purity titanium dioxide or chemical environments, with a price of $20,000-$50,000+.

Wear-resistant steel (NM400/500): Suitable for high-wear environments, price $25,000− $60,000.

3. Lifting height affects price

Below 10 meters: The price is relatively low, about $5,000− $15,000.

10-30 meters: Price $15,000− $35,000 (reinforced structure required).

More than 30 meters: Customization required, price $35,000+ (such as hoists for storage centers).

4. Lifting volume affects price

5-10 tons/hour: small equipment, price $5,000− $15,000.

10-30 tons/hour: medium-sized equipment, price $15,000− $30,000.

More than 30 tons/hour: large equipment, price $30,000− $60,000+.

How to choose the Titanium dioxide conveying bucket elevator?

1. Determine the conveying capacity: Determine the hourly conveying capacity according to production requirements.

2. Determine the lifting height: Determine the height to be lifted according to the process layout.

3. Determine the material characteristics: Understand the material characteristics such as particle size, density, temperature, humidity, etc.

4. Select the hopper form: Select a suitable hopper according to the material characteristics and unloading method.

5. Select the traction component: Select a belt or chain according to the conveying capacity and lifting height.

6. Select the drive device: Calculate the required drive power according to the conveying volume and lifting height.

7. Select the appropriate material: Select wear-resistant and corrosion-resistant materials according to the characteristics of the conveyed material.

8. Consider the installation environment: Consider the installation space limitations and environmental conditions.