Talc powder bucket elevator

Special equipment for vertical conveying of Talc Powder materials

| Lifting height | 10-40 meters, customized according to specific needs. |

| Conveying capacity | 15-800 m³/h |

| Hopper type | Deep bucket (fine powder), shallow bucket (poor fluidity) |

| Drive power | 3-30 kW (adjusted according to height and conveying capacity) |

| Material | Powdered, granular, small block materials (such as talcum powder, cement, coal powder, etc.) |

What is talc powder bucket elevator?

Talc powder bucket elevator is a kind of equipment specially used for vertical conveying of talc powder or other fine powder materials. Talc powder is a light and fine powder widely used in cosmetics, medicine, coatings, plastics and other industries. Due to its special physical properties (such as light weight and easy to raise dust), the design of talc powder bucket elevator needs to meet the requirements of efficient, dust-free and stable conveying.

What is the purpose of talc powder bucket elevator?

Efficient transportation: suitable for rapid vertical transportation of large quantities of talc powder, improving production efficiency and reducing labor costs.

Space saving: The vertical design takes up little space, is suitable for use in limited production environments, and optimizes factory layout.

Material protection: The sealed design prevents talc powder from leaking during transportation, reducing material loss and environmental pollution.

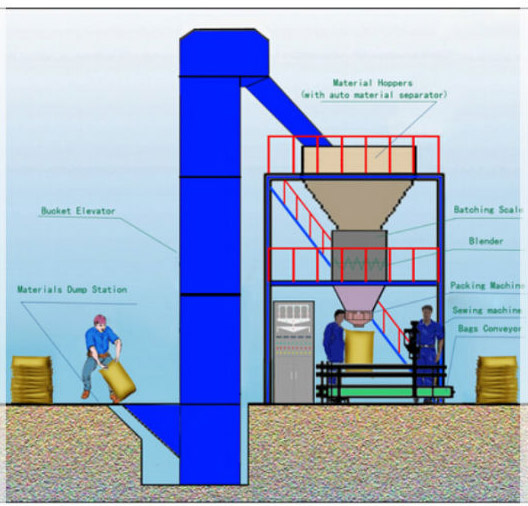

Automated production: It can be linked with other equipment (such as mixers and packaging machines) to achieve automated production and improve the efficiency of the overall production line.

Strong adaptability: It is suitable for talc powder of different particle sizes and characteristics, and can be customized according to production needs to meet diverse industrial applications.

What are the applications of talc powder bucket elevator?

Cosmetics Industry: Talc powder is a common ingredient in products like baby powder, face powders, and other cosmetics.

Pharmaceuticals: Talc is used as a glidant in tablet manufacturing.

Paints and Coatings: Talc acts as a filler and extender in paint formulations.

Plastics and Rubber: Talc is used as a reinforcing filler in plastics and rubber products.

What are the advantages of talc powder bucket elevator?

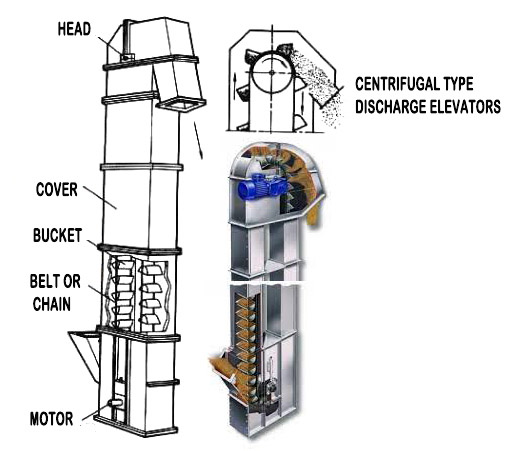

1. Enclosed Design: To prevent dust emissions and contamination, talc powder bucket elevators are typically fully enclosed. This ensures a clean working environment and minimizes product loss. 2. Corrosion-Resistant Materials: Since talc is non-abrasive, the elevator can be constructed from materials like stainless steel or coated carbon steel to resist corrosion and ensure longevity.

3.Gentle Handling: Bucket elevators for talc powder are designed to handle the material gently to avoid degradation or clumping of the fine particles.

4.Dust-Tight Seals: Special seals and gaskets are used to prevent dust leakage at connection points, ensuring compliance with environmental and safety regulations.

5.Explosion-Proof Options: If the talc powder is being transported in an environment where explosive dust could be a concern, the elevator can be equipped with explosion-proof motors and components.

6.Customizable Buckets: The buckets attached to the belt or chain can be customized in size and shape to optimize the handling of talc powder.

Talc powder bucket elevator parameters

| Model | Max feed size(mm) | Capacity(T/H) | Lifting speed(m/s) | Belt width(mm) | Lifting height(m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | |

| TD315 | 45 | 17-40 | 1.6 | 400 | |

| TD400 | 55 | 24-66 | 1.8 | 500 | |

| TD500 | 60 | 38-92 | 1.8 | 600 | |

| TD600 | 70 | 85-142 | 2 | 700 |

| Application scenario | Lifting capacity | Lifting height | Key configuration |

| Talc finishing line of an international cosmetics raw material supplier | 8 tons/hour | 15 meters (from grinding workshop to finished product silo) | 304 stainless steel material (food grade), anti-static belt design, nitrogen protection system (explosion-proof) |

| Automatic batching system for talcum powder filler in modified plastics factory | 12 tons/hour | 22 meters (cross-floor transportation) | Wear-resistant ceramic lined bucket, variable frequency speed control, central dust removal interface |

| Talc powder-calcium carbonate mixing section in large paper mills | 20 tons/hour | 18 meters (from discharge port to mixing tank) | Double-row chain bucket structure, moisture-proof motor (IP65 protection), online weighing feedback system |

| Talc powder pre-packaging lifting system in GMP pharmaceutical factory | 5 tons/hour | 10m | Fully enclosed aseptic design, 316L stainless steel, CIP cleaning pipeline |

How to choose talc powder bucket elevator?

1. Talc Material Characteristics

Particle size and density: Understand the particle size distribution and density of talc to select the appropriate bucket type and elevator specifications.

Material selection

General industrial grade: Q235 + wear-resistant coating

Food/medical grade: 304/316L stainless steel

Anti-static requirements: carbon steel + conductive coating

2. Lifting height and lifting amount selection

| Selection parameters | Selection points |

| Lifting height |

≤15m: belt type (economic type) 15-30m: chain type (NE type) >30m: multi-stage series |

| Lifting capacity |

<5t/h: small (TH type) 5-50t/h: Medium (NE type) >50t/h: Customized |

| Working temperature | Normal temperature: Standard configuration,>80℃: Heat-resistant chain/belt |

4. Feeding and unloading methods

Feeding method

Gravity feeding: suitable for ordinary talcum powder with good fluidity (inclination ≥ 45°)

Forced feeding: recommended for high-precision conveying (with screw feeder installed)

Discharging method

Centrifugal unloading: suitable for medium and low speed (<2m/s), fine powder (above 200 mesh)

Gravity unloading: suitable for coarse particles and high-humidity materials

Hopper selection comparison table

| Hopper type | Applicable scenarios | Advantages |

| Shallow bucket (Type A) | Fine powder with good fluidity (above 400 mesh) | Clean unloading |

| Deep bucket (Type B) | Ordinary industrial grade talcum powder (80-325 mesh) | Large loading capacity |

| Scale bucket (Type C) | Modified talcum powder with trace moisture | Anti-adhesion |

5. Environmental conditions

Consider the temperature, humidity and dust conditions of the working environment and select corrosion-resistant and wear-resistant materials.

6. Drive mode

Select the appropriate motor power and drive mode (such as motor drive or hydraulic drive) to ensure the stability and efficiency of the equipment.