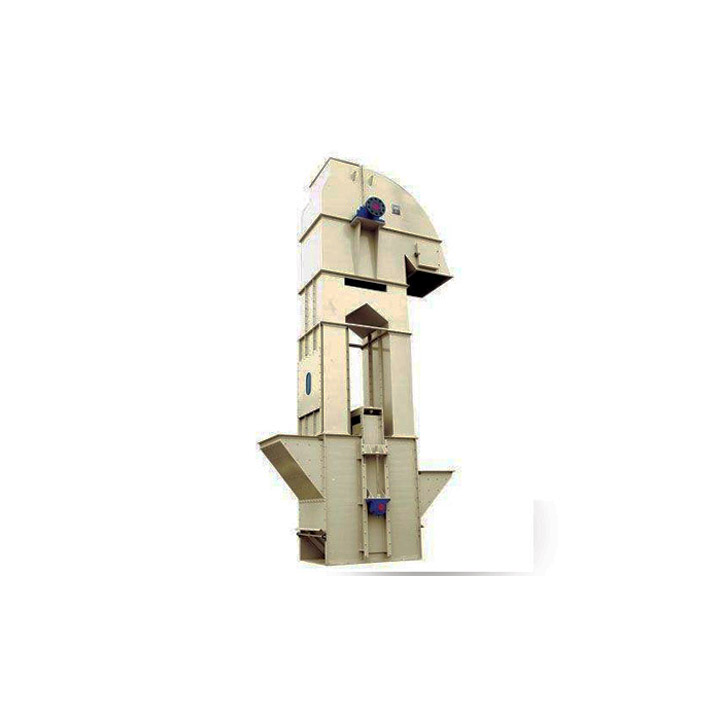

TH type chain bucket elevator

Heavy-duty bulk material vertical conveyors designed for the cement, coal, fertilizer and mining industries

| Lifting height | 10m ~ 40m (customizable) |

| Conveying capacity | 10t/h ~ 200t/h |

| Belt width | 300mm ~ 1000mm |

| Working temperature | -20°C ~ 50°C |

| Motor power | 2.2kW ~ 45kW (depending on lifting capacity and height) |

| Bucket capacity | 3L ~ 10L (designed according to material type and conveying volume) |

What is TH type chain bucket elevator?

TH type chain bucket elevator is a kind of conveying equipment widely used for vertical lifting of materials, especially suitable for lifting granular, powdery and block materials. The equipment consists of chain, lifting bucket, drive device, frame, supporting wheel and other components. It is widely used in metallurgy, fertilizer, cement, grain, mining and other industries, especially suitable for conveying bulk materials.

What are the advantages of TH type chain bucket elevator?

Robust Chain & Bucket System: Forged alloy steel for long-lasting performance.

High Capacity: Handles powder, granules, and lump materials (e.g., clinker, gravel).

Low Energy Consumption: Optimized drive system reduces operational costs.

Customizable: Available in TD250, TH315, TH400 models with varied speeds.

How does TH type chain bucket elevator work?

When the TH type chain bucket elevator is in operation, material is fed into a hopper at the bottom. As the chain moves upward, the hopper scoops up the material and conveys it to the top. At the top, the chain rotates around a wheel, causing the hopper to flip and discharge the material through a discharge chute. The empty hopper then returns to the bottom and the process is repeated, continuously lifting materials such as grain, cement or coal to higher levels.

What industries can TH type chain bucket elevator be used in?

Metallurgical industry: lifting ore, metallurgical raw materials and other materials.

Cement plant: used to lift cement clinker, limestone, coal powder and other materials.

Grain processing: lifting granular materials such as rice, wheat, corn, etc.

Fertilizer industry: lifting granular materials such as compound fertilizer, phosphate fertilizer, nitrogen fertilizer, etc.

Coal mines and mines: lifting block materials such as ore and coal.

Chemical industry: lifting granular and powdered chemical raw materials.

TH type chain bucket elevator structure

Casing: The sturdy shell can protect the internal components and prevent external pollution and wear.

Lifting bucket: Used for loading and lifting materials, common materials include steel plates, plastics, rubber, etc.

Chain: High-strength alloy steel chain is used to ensure long-term and efficient operation of the equipment.

Drive device: Equipped with motors, reducers, couplings and other equipment, responsible for providing power.

Support wheel: Used to support the transmission part of the chain and bucket elevator to ensure the smooth operation of the equipment.

Discharging device: Located at the top of the elevator, it is used to discharge the lifted materials.

TH type chain bucket elevator parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Hopper form | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Conveying volume m/h | Ordinary type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Improved version | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Hopper | Hopper width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Dou Rong L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Ordinary type | 500 | 512 | 688 | ||||||||||||||

| Improved version | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter × pitch) mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Ordinary type | 9 | 7 | 7 | ||||||||||||||

| Improved version | - | 5 | 5 | |||||||||||||||

| Hopper running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Material*large piece size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

TH type chain bucket elevator customer case

| Application scenario | Lift height | Lifting capacity | Motor Power | Customer feedback |

| A large cement plant uses TH400 chain bucket elevator to transport high-temperature clinker (≤250°C) from the kiln tail to the clinker storage, replacing the original belt conveyor system to solve the problems of dust leakage and equipment wear. | 32 meters | 120t/h | 22 kW | The equipment has been running for 3 years without major maintenance, and the wear rate has been reduced by 60%; the fully sealed structure makes the on-site dust concentration meet the standard (<10mg/m³); the frequency conversion control saves energy by 15% |

| A coal-fired power plant in Southeast Asia uses TH315 chain bucket elevator to vertically lift the fly ash collected by the electrostatic precipitator to the ash storage bin to handle highly abrasive fly ash. | 28 meters | 50 tons/hour | 15 kW | Compared with the old elevator, the chain breakage frequency of TH315 has been reduced from once a month to once a year, and the maintenance cost has been reduced by 70%. |

| A domestic compound fertilizer manufacturer selected TH250 chain bucket elevator to lift the wet granular ammonium from the packaging workshop to the batching warehouse on the 6th floor (ambient humidity>80%). | 18 meters | 30 tons/hour | 7.5kW (IP55 protection level) | Solve the problem of material adhesion (residue in the bucket <0.5%); anti-corrosion design extends the equipment life from 2 years to 5 years |

How to select TH type chain bucket elevator?

1. Material characteristics

The characteristics of the material determine the structure, material and applicable technical parameters of the elevator. Specifically, the following points should be considered:

Material particle size: If the material particles are large or irregular in shape (such as coal blocks, large-particle cement, ore, etc.), it is necessary to select equipment with a larger hopper volume, and at the same time ensure that the chain and bucket elevator can withstand the impact and load of the material.

Material density: The density of the material affects the conveying capacity. For heavy materials (such as ore, granular cement, etc.), it is necessary to select a model that can provide a larger lifting capacity, while considering the strength of the chain and drive system.

Material temperature: If the temperature of the conveyed material is high (such as hot cement, steel raw materials, etc.), materials with high temperature resistance and special coatings should be selected to avoid damage to the chain and lifting bucket.

Material corrosiveness: For highly corrosive materials (such as fertilizers, chemical powders, etc.), it is necessary to select corrosion-resistant materials and designs with stronger sealing.

Material humidity: If the material humidity is high (such as wet clay, wet coal, etc.), it is necessary to select equipment that can prevent material adhesion, and it may be necessary to install anti-blocking devices or heating devices to avoid equipment clogging due to excessive material viscosity.

2. Lifting height

The lifting height is an important factor that must be considered when selecting a TH-type chain bucket elevator. The lifting height determines the power, chain and equipment configuration required for the elevator.

Low lifting height (below 10m): If only low-height conveying is required, standard TH-type equipment can be selected, and special customization is usually not required.

Medium-high lifting height (10m-30m): It is necessary to ensure that the driving power and chain strength of the equipment are sufficient to support the vertical lifting of materials, and the motor power and chain strength may need to be strengthened.

High lifting height (above 30m): When the lifting height is high, the stability of the equipment, the power of the drive system and the tensile strength of the chain need to be considered to ensure that the equipment can operate efficiently and stably.

3. Lifting capacity

The lifting capacity refers to the amount of material that the equipment can convey per unit time, usually in "tons/hour" (t/h).

Low lifting capacity (10-30t/h): Suitable for small-scale production or enterprises with low material requirements.

Medium lifting capacity (30-100t/h): Suitable for medium-sized production lines and can meet regular production needs.

Large lifting capacity (above 100t/h): suitable for large-scale production, especially large cement plants, mines and other occasions that require efficient transportation.

According to the type, density and production requirements of the material, select the lifting capacity that can meet the highest demand and ensure the stability and durability of the equipment in long-term operation.

4. Hopper design

The hopper is a vital component in the chain bucket elevator. The correct hopper design is crucial to the lifting efficiency of the material and the service life of the equipment.

Hopper capacity: Select a hopper with appropriate capacity according to the bulk density, particle size and conveying speed of the material. Heavier or larger materials usually require a larger hopper to avoid blockage or instability caused by a small hopper body.

Hopper shape: Generally, the hopper of the TH type elevator is a closed design, which helps prevent the material from leaking or causing contamination during the lifting process. Choose a suitable hopper shape (such as V-shaped, U-shaped or square) to ensure that the material can enter and discharge smoothly.

Hopper spacing: The spacing of the hopper should be designed according to the type of material conveyed and the lifting height. If the material particles are large, the hopper spacing can be appropriately increased to avoid clogging.

Hopper material: The hopper should be selected according to the characteristics of the material. For example, when lifting sticky materials, a hopper with a self-cleaning function can be selected to prevent material adhesion.

5. Material selection

According to the characteristics of the material and the working environment, it is very important to choose the right material, mainly considering the following aspects:

Chain material: The chain is the core component of the elevator, and the commonly used materials are alloy steel, stainless steel, carbon steel, etc. If the material temperature is high or corrosive, it is recommended to use high temperature resistant or corrosion resistant alloy chain. Stainless steel chain is suitable for highly corrosive chemical products.

Lifting bucket material: Common lifting bucket materials include steel plate, aluminum alloy, plastic, etc. For highly corrosive and high temperature materials, corrosion-resistant and high temperature resistant materials should be selected. For granular materials, metal hoppers can be selected; for lightweight materials, plastic hoppers can effectively reduce the weight of the equipment.

Drive device material: The drive device should be selected with high-strength materials to ensure reliability during long-term high-load operation. The motor and reducer should be selected according to the required power and efficiency requirements.

Wear-resistant and anti-corrosion coatings: For working conditions prone to wear or corrosion, it is recommended to use wear-resistant coatings or anti-corrosion coatings to enhance the service life of the equipment.

TH Chain Bucket Elevator

TH Chain Bucket Elevator TB Bucket Elevator

TB Bucket Elevator

GTD Bucket Elevator

GTD Bucket Elevator