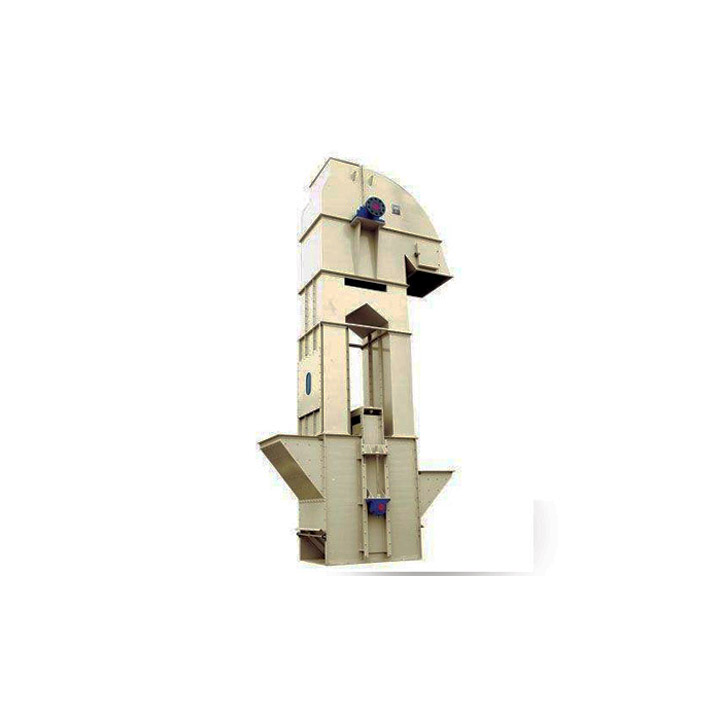

TH Chain Bucket Elevator

The chain drives the hopper to transport various bulk materials such as powder, granules and small blocks vertically. The lifting height can reach 60 meters. The price ranges from $350 to $7,300.

| Bucket volume | 5.2~10L |

| Bucket speed | 1.25m/s |

| Motor power | 5.5~7.5KW |

| Conveying capacity | 280-625mm |

| Height | 60m |

| Hopper capacity | 4.4-38L |

What is TH Chain Bucket Elevator?

TH Chain Bucket Elevator is a heavy-duty vertical conveyor designed for transporting bulk materials such as cement, coal, grain, sand, and minerals. It utilizes high-strength TH chains and a reinforced hopper to lift materials vertically from one location to a specified height. It can reach heights of up to 60 meters and can lift 20-800 cubic meters per hour. Its high lifting capacity, long service life, and low maintenance requirements make it an ideal choice for industries requiring continuous material conveying.

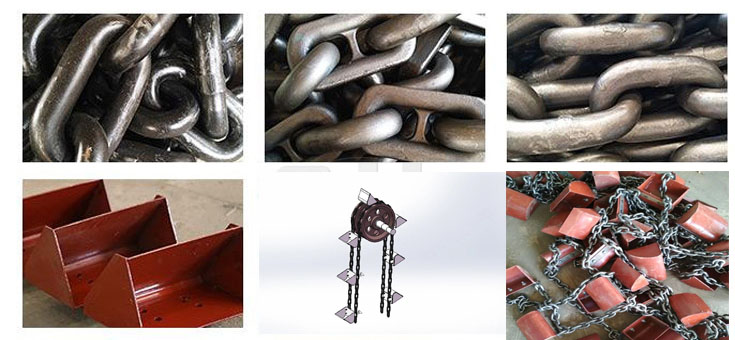

The TH Chain Bucket Elevator uses a high-strength chain as a traction member, which is firmly connected to the hopper. The chain undergoes special heat treatment, has strong wear resistance and a long service life. It can withstand high-temperature materials ≤ 250°C, and some operating conditions can reach 400°C. The chain is available in high-strength round link chain (the mainstream choice, wear-resistant and impact-resistant) and alloy steel cast chain (suitable for high-temperature and corrosive materials).

TH Chain Bucket Elevator Video

What are the advantages of TH Chain Bucket Elevator?

The TH Chain Bucket Elevator utilizes high-strength forged chain for a durable, wear-resistant structure. Its large hopper and high capacity make it particularly suitable for lifting medium- and large-volume, abrasive materials. It offers high lifting heights, high conveying capacity, stable and reliable operation, and excellent sealing to prevent dust from spreading.

High-strength chain: low-alloy high-strength round link chain is used, which has been specially heat-treated and has excellent tensile strength and wear resistance, ensuring long-term and stable operation of the equipment.

Large-capacity hopper: The hopper has a large volume, high layout density, a wide lifting range, and can carry up to 50 tons/hour.

Good sealing: Each section and inspection door is equipped with a sealing device to prevent dust leakage and keep the production environment clean.

Efficient drive system: The drive wheel adopts an integral structure, and the surface is specially reinforced, which is easy to operate, high in strength and good in wear resistance.

Custom bucket options – deep shovel, shallow shovel or side-mounted design

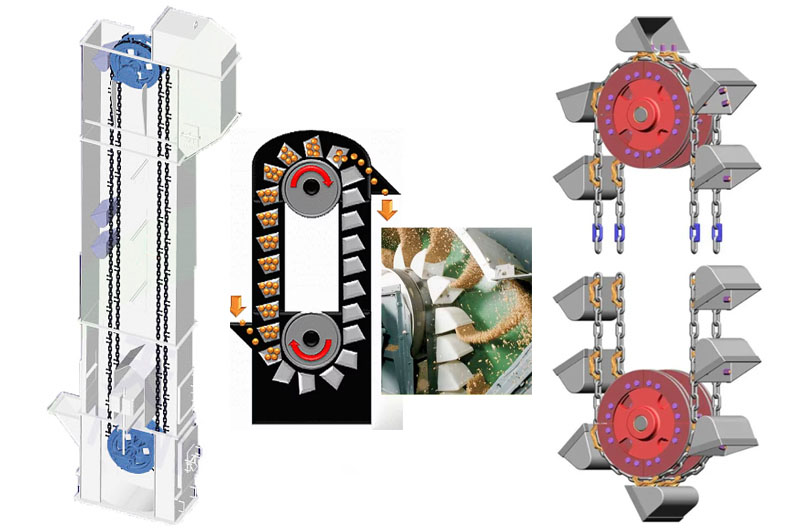

How does TH Chain Bucket Elevator work?

TH Chain Bucket Elevator drives the chain and bucket to circulate in a closed casing through a drive device. The material enters the bucket from the lower feed port, is lifted to the top by the chain, and is discharged to the discharge port under the action of centrifugal force, thus realizing vertical transportation of the material.

TH Chain Bucket Elevator Parameters

| Model | HL300 | HL400 | TH315 | TH400 | TH500 | TH630 | TH800 | ||||||||

| Bucket form | Q | S | Q | S | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh | |

| Capacity(m3/h) | 24 | 28 | 45 | 47 | 21 | 36 | 36 | 56 | 45 | 70 | 68 | 110 | 87 | 141 | |

| Bucket width(mm) | 300 | 400 | 315 | 400 | 500 | 630 | 800 | ||||||||

| Bucket volume (L) | 4.4 | 5.2 | 10 | 10.5 | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 | 23.3 | 37.5 | |

| Pitch of buckets(mm) | 512 | 512 | 512 | 512 | 688 | 688 | 920 | ||||||||

| Chain specification | Φ18×64 | Φ18×64 | Φ18×64 | Φ18×64 | Φ22×86 | Φ22×86 | Φ26×92 | ||||||||

| Sprocket pitch diameter(mm) | 630 | 630 | 630 | 710 | 800 | 900 | 1000 | ||||||||

| Bucket speed(m/s) | 1.4 | 1.4 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | ||||||||

| The maximum size of material(mm) | 40 | 50 | 45 | 55 | 65 | 75 | 85 | ||||||||

What are the applications of TH Chain Bucket Elevator?

TH Chain Bucket Elevator adopts mixed or gravity unloading and excavation loading, and is suitable for conveying powdery, granular and small-particle bottom abrasive materials with a bulk density less than 1.5t/m3 and easy to dig out, such as coal, cement, gravel, sand, limestone, gypsum, ore, fertilizer, chemical raw materials, wheat, corn, rice and other materials.

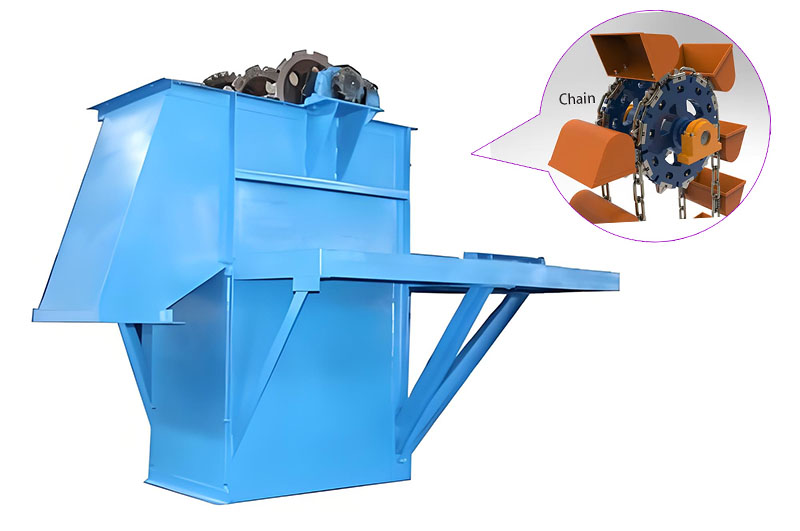

What are the structures of TH Chain Bucket Elevator?

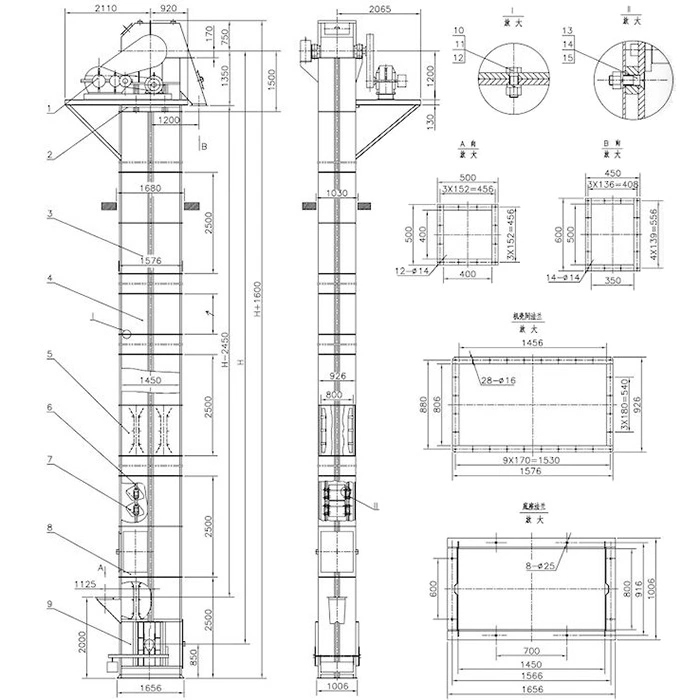

TH Chain Bucket Elevator mainly consists of a hopper, a chain, an upper device, a lower device, an intermediate section, a driving device, etc.

Running parts-consisting of hopper and special ring chain, the chain has high tensile strength and good wear resistance.

Driving device - adopts a variety of driving combinations to drive, (depending on the actual needs of the user). The driving platform is equipped with a maintenance frame and a railing. The drive system is divided into two types: left and right.

The upper device - is equipped with rails (double-row chains), backstops, and the discharge port is equipped with an anti-return rubber plate.

Intermediate section - Part of the intermediate section is equipped with a track (double chain) to prevent the chain from swinging during operation.

Lower unit - fitted with automatic tensioner.

TH chain bucket elevator has two types of hoppers:

Zh type (medium-deep bucket) is generally suitable for conveying wet, caking, and difficult-to-throw materials, such as wet sand, molding sand, fertilizer, alkali powder, etc.

Sh type (deep bucket) is suitable for conveying dry, loose and easy to throw materials, such as cement, clinker, gravel, coal, etc., and its conveying capacity is also larger than that of Zh type.

TH Chain Bucket Elevator Manufacturer

Dahan TH Chain Bucket Elevator is a leading manufacturer dedicated to providing customers with durable, heavy-duty vertical conveying solutions. With 15 years of experience in R&D and production, we offer TH Chain Bucket Elevators. Our TH series includes models such as the TH160, TH200, TH250, TH315, TH400, TH500, TH630, TH800, and TH1000. Lift capacities range from 25 to 365 m³/h, and lifting heights can be customized to meet your process requirements, reaching over 60 meters. The elevator body is constructed of Q235B or higher high-strength steel, and the traction components utilize high-strength alloy steel forged round-link chain, offering exceptional wear resistance and tensile strength. This ensures reliable and stable handling of high-temperature (≤250°C) and high-density materials. Our factory implements strict quality control from cutting, welding, machining, and assembly to ensure substandard quality. Pricing starts from just $350.

TH Chain Bucket Elevator Customer Case

| Customer Cases | Application Scenarios | Material Lifting | Lifting Capacity (m³/h) | Lifting Height (m) | Models | Key Points and Results |

| A Cement Plant in China | Cement Production Line | Cement Raw Meal and Clinker | 185 | 40 | TH630 | High conveying capacity, stable and reliable operation. Forged chain is wear-resistant and high-temperature resistant (≤250°C), effectively handling highly abrasive materials. |

| Vietnamese aluminum company | Non-ferrous metal smelting | Bauxite and alumina powder | 94 | 35 | TH400 | Suitable for high-temperature dusty environments. Low-alloy steel forged chain undergoes carburizing and quenching treatment, resulting in extremely high tensile strength and wear resistance. |

| A fertilizer plant in Pakistan | Ammonium phosphate production unit | Fertilizer raw materials and return materials | 58-94 | 20-30 | TH400 | Patented chain hook reinforcement technology solves the problem of chain hook breakage under alternating stress, significantly reducing failure rates and ensuring continuous production. |

| A thermal power plant in India | Coal conveying system | Coal | 118 | 28 | TH500 | Withstands temperatures below 250°C. Manganese steel round link chain offers high tensile strength and excellent wear resistance, making it suitable for long-term heavy-load operation and reducing downtime for maintenance. |

TH type chain bucket elevator

TH type chain bucket elevator