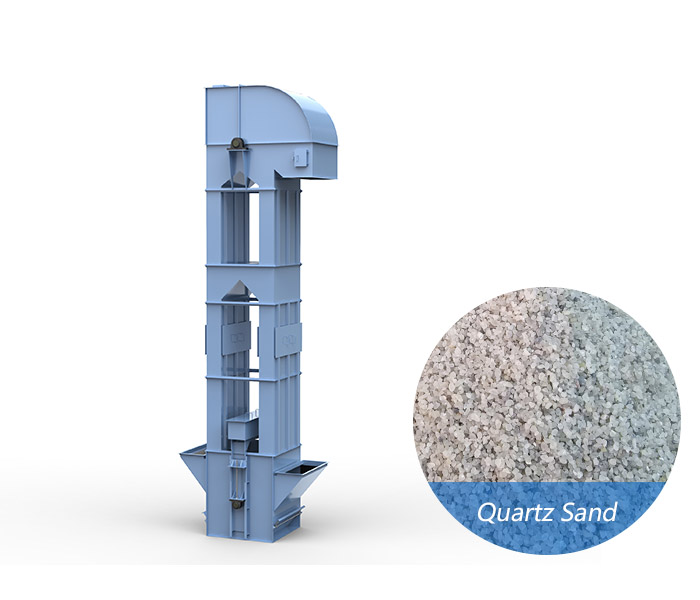

Quartz sand bucket elevator

Equipment that can transport quartz sand vertically from the ground to a high place

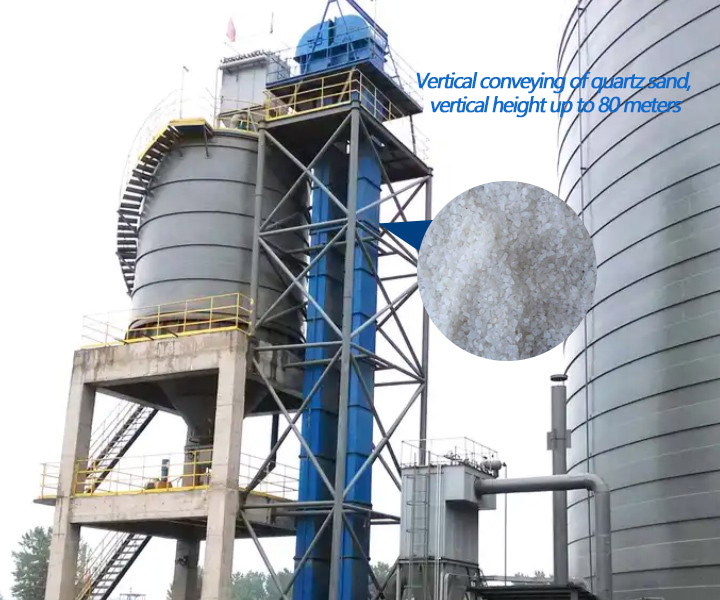

| Lifting height | 10-80 m, Can be customized according to needs |

| Conveying capacity | 10-300 t/h |

| Hopper capacity | 5-50 L |

| Motor power | 5.5-75 kW |

| Operating speed | 0.8-3.5 m/s |

What is Quartz Sand Bucket Elevator?

Quartz sand bucket elevator is a kind of equipment specially used for vertical conveying of granular materials such as quartz sand. It lifts quartz sand from low to high through a hopper fixed on a chain or belt, and is widely used in glass manufacturing, casting, chemical industry and other industries.

What are the functions of quartz sand bucket elevator?

1. Vertical conveying: Efficiently lift quartz sand from low to high.

2. Continuous operation: Suitable for production lines that require continuous conveying.

3. Reduce dust: The sealing design effectively reduces the leakage of quartz sand dust.

4. Strong wear resistance: Wear-resistant materials are used to adapt to the high wear characteristics of quartz sand.

5. Energy saving and environmental protection: Low energy consumption design meets the environmental protection requirements of modern industry.

What are the applications of quartz sand bucket elevator?

1. Glass manufacturing industry: used for the transportation of quartz sand raw materials.

2. Casting industry: Convey quartz sand for casting.

3. Chemical industry: used for vertical lifting of chemical raw materials.

4. Building materials industry: transporting quartz sand for the production of tiles, ceramics, etc.

5. Water treatment industry: used for the transportation of quartz sand for filtration.

Quartz Sand Bucket Elevator Customer Cases

| Application Scenario | Amount of improvement | Raise height | Features |

| Vertical lifting of raw quartz sand from ground storage to the washing and screening line. | 50 tons/hour | 15 meters | Stainless steel buckets to prevent contamination, sealed design to reduce dust |

| Transporting high-purity quartz sand to the glass melting furnace. | 80 tons/hour | 20 meters | Food-grade material construction, wear-resistant chains for long-term use |

| Feeding quartz sand into molding machines for metal casting. | 30 tons/hour | 10 meters | Heavy-duty design for abrasive sand, easy maintenance access points |

| Elevating filter-grade quartz sand to packaging and distribution lines. | 20 tons/hour | 8 meters | Gentle handling to prevent particle breakdown, corrosion-resistant frame |

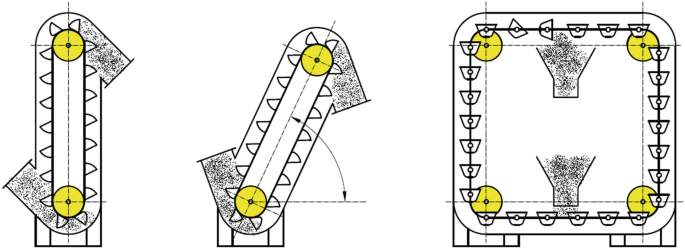

How does the quartz sand bucket elevator work?

Quartz sand bucket elevator introduces quartz sand through the bottom feed port, and uses the hopper installed on the vertical or inclined annular traction member to lift the quartz sand to the top driven by the driving device, and unloads it by gravity or centrifugal force. The empty hopper is recycled back to the bottom to achieve continuous vertical transportation of quartz sand.

Quartz Sand Bucket Elevator Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

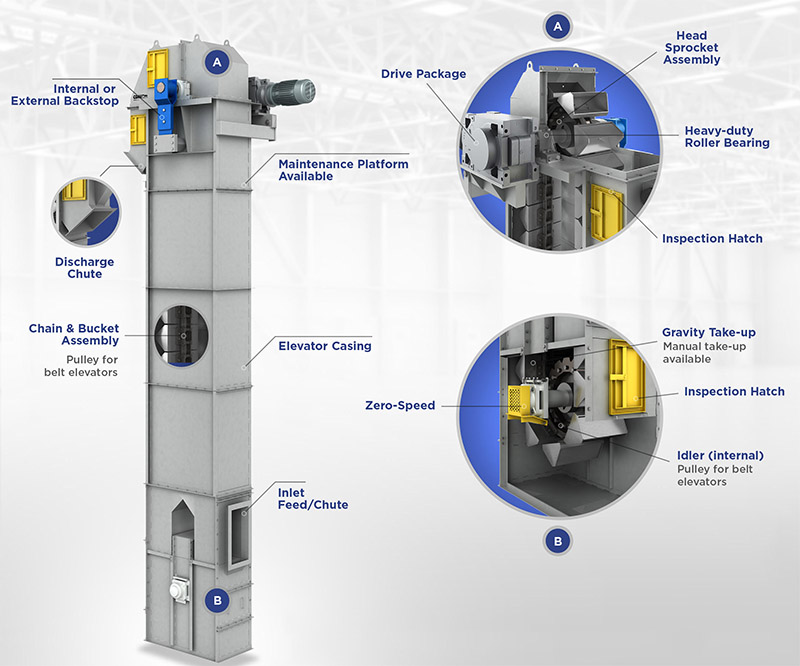

What structures does the quartz sand bucket elevator consist of?

1. Head device: including drive wheel, backstop and discharge port.

2. Tail device: including tension wheel and self-cleaning structure to prevent material adhesion.

3. Hopper: high-strength plastic or iron hopper, wear-resistant and large capacity.

4. Chain or belt: used to fix and drive the hopper.

5. Shell: sealed design to reduce dust leakage.

How to select Quartz Sand Bucket Elevator?

Analyze Quartz Sand Characteristics

Particle Size - Fine sand (<0.5mm): Use deep buckets to prevent spillage;Coarse sand (0.5–2mm): Opt for shallow buckets with higher spacing.

Abrasiveness - High-abrasion sand: Choose NM400 steel/manganese steel buckets and forged chains;Low-abrasion sand: Polyethylene (PE) buckets reduce weight and cost.

Moisture Content:Wet sand: Select perforated buckets for drainage or add vibrators to prevent clumping.

Determine Lifting Height & Capacity

Height Range:Short lifts (<15m): Standard belt-driven elevators;Tall lifts (15–50m+): Chain-driven with reinforced guides (e.g., Z-type elevators).

Capacity Requirements:Small-scale (10–50 T/H): Light-duty models (e.g., TD250); Industrial (50–200 T/H): Heavy-duty designs (e.g., TH630 with dual chains).

Select Material & Construction

Buckets: Stainless steel (316L) for high-purity applications (e.g., glass manufacturing);Carbon steel with ceramic lining for abrasive sand in mining.