Plastic granule bucket elevator

Used for vertical conveying of plastic particles (lifting plastic particles from a low place to a high place through the hopper to achieve vertical conveying of plastic particles

Bucket Material:Plastic, Stainless Steel, or HDPE

Bucket Capacity:1L to 30L per bucket

Conveyor Speed:0.5 - 2.5 m/s

Lifting Height:2m - 30m

Belt/Chain Type:Rubber Belt, Steel Chain

Load Capacity:1 - 100 tons per hour

Power Requirement:0.5 kW - 15 kW

What is Plastic granule bucket elevator?

A plastic granule bucket elevator is a specialized material handling system designed to vertically transport plastic granules or pellets efficiently and gently. It's a type of conveyor that uses a series of buckets attached to a rotating belt or chain to lift the plastic granules. These elevators are crucial in various industries that process or utilize plastic materials.

What are the applications of Plastic Granule Bucket Elevator?

Plastic granule bucket elevators find applications across a wide range of industries, including:

Plastics Manufacturing: Moving raw materials (plastic resins/pellets) to mixers, extruders, or storage silos.

Recycling: Transporting recycled plastic granules for reprocessing.

Packaging: Feeding plastic pellets into packaging machines.

Compounding: Moving blended plastic materials to storage or further processing.

Chemical Processing: Handling plastic-based chemicals in granular form.

Food Processing: While less common, some food products might use similar elevators if they are granular and non-sticky.

How Does a Plastic Granule Bucket Elevator Work?

Plastic Granule Bucket Elevator realizes vertical conveying of granular materials through continuous cycle operation: the feed hopper at the bottom of the equipment feeds plastic granules evenly, and the hopper fixed on the conveyor belt or chain completes the loading of granules when passing through the material layer; the conveying system driven by the motor drives the fully loaded hopper to be lifted vertically to the top, and the granules are accurately unloaded into the discharge trough by centrifugal force or gravity flipping; the empty hopper then returns to the bottom along the downward side, forming a closed continuous conveying cycle. The entire process is equipped with an anti-return device and a speed control system to ensure that the conveying efficiency can reach 2-20 tons/hour, which is particularly suitable for feeding the automated production line of plastic granules such as PE/PP/PET.

What are the advantages of Plastic Granule Bucket Elevator?

Gentle Handling: Designed to minimize damage to the plastic granules.

Vertical Conveying: Efficiently lifts materials to significant heights.

Continuous Operation: Provides a consistent flow of material.

Customizable: Can be tailored to specific capacity and height requirements.

Enclosed Design: Often enclosed to prevent dust and spillage.

Various Materials: Can be constructed from different materials (e.g., stainless steel, carbon steel) depending on the application.

What are the structural components of Plastic Granule Bucket Elevator?

Head Section: Contains the drive motor, pulley/sprocket, and discharge point.

Boot Section: Located at the bottom, includes the loading hopper and take-up pulley/sprocket.

Leg Casings: Enclose the belt or chain and buckets.

Buckets: Attached to the belt or chain, these hold the plastic granules.

Belt or Chain: Provides the means of moving the buckets.

Drive Unit: Motor and gearbox to power the elevator.

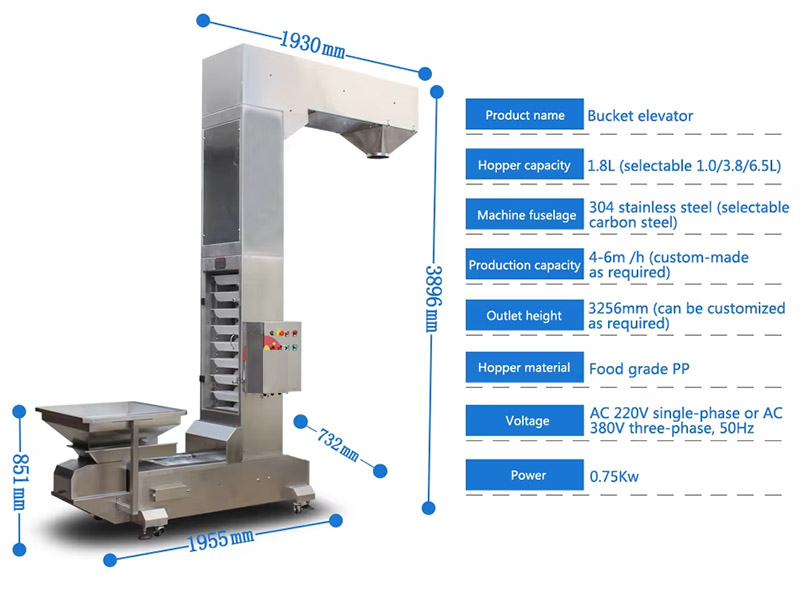

Plastic Granule Bucket Elevator Parameters

Capacity: The amount of material the elevator can handle per hour (e.g., kg/h or tons/h).

Lift Height: The vertical distance the material is lifted.

Bucket Size: The volume of each bucket.

Belt or Chain Speed: The speed at which the belt or chain moves.

Motor Power: The power of the drive motor.

Material Properties: Characteristics of the plastic granules (e.g., size, density, flowability).

Plastic Granule Bucket Elevator Customer Case

| Application Scenario | Material Characteristics | Lifting Amount | Lifting Height | Select Equipment |

| Transport the crushed and cleaned PP granules from the cleaning machine to the drying tower | 3-5mm irregular PP recycled granules | 6t/h | 8.5 meters | NE50 plate chain elevator (increased hopper spacing, conductive carbon fiber chain, 304 stainless steel shell) |

| PET bottle flake processing plant: automated conveying of bottle flakes from sorting machine to extruder | 8-12mm flake PET | 15 tons/hour | 12m | TGD200 belt elevator (with textured rubber belt surface, dustproof IP54, equipped with metal detector) |

| PE film granulation workshop: PE granules are conveyed from granulator to finished product warehouse | 2-3mm cylindrical granules | 8 tons/hour | 18m | TH160 chain hoist (hopper Teflon coating, double sealed observation window, variable frequency speed control) |

How to select Plastic granule bucket elevator?

Choosing the right bucket elevator involves considering several factors:

Material Characteristics: The type of plastic, its size, density, and flow properties.

Capacity Requirements: How much material needs to be moved per hour.

Lift Height: The vertical distance the material needs to be conveyed.

Space Constraints: The available space for the elevator.

Environmental Conditions: Temperature, humidity, and other environmental factors.

Budget: The cost of the elevator and installation.

Consulting with a reputable material handling equipment supplier is crucial for proper selection and ensuring the elevator meets the specific needs of the application. They can help with calculations, customization, and installation.