Phosphate rock bucket elevator

Material handling equipment for vertical or inclined transport of phosphate rock in industries such as mining, fertilizer production and chemical processing.

| Lifting height | 10-120 meters, customized according to specific needs. |

| Conveying capacity | 10-120t/h |

| Hopper capacity | 0.5-50 L |

| Motor power | 3-25 kW |

| Material | carbon steel, stainless steel, etc. |

| Bucket | Q-type (light bucket), H-type (arc bottom bucket), Zd-type (middle deep bucket), and Sd-type (deep bucket) |

What is a Phosphate Rock Bucket Elevator?

A phosphate rock bucket elevator is a mechanical device used to lift phosphate rock from a lower level to a higher level. It consists of buckets attached to a belt or chain that rotates around pulleys or sprockets. The buckets scoop up the phosphate rock at the bottom, carry it vertically or at an incline, and discharge it at the top.

What are the advantages of phosphate rock bucket elevator?

-High Capacity: Designed to handle large volumes of phosphate rock.

-Durability: Constructed with robust materials to withstand abrasive and heavy loads.

-Versatility: Can operate in vertical or inclined configurations.

-Low Maintenance: Simple design with minimal moving parts for easy maintenance.

-Dust Control: Enclosed design to minimize dust and material spillage.

-Customizable: Bucket size, speed, and material can be tailored to specific needs.

What are the applications of Phosphate rock bucket elevator?

Phosphate rock bucket elevators are widely used in industries where phosphate rock is a key raw material:

-Mining Industry: Transporting phosphate rock from mines to processing plants.

-Fertilizer Production: Moving phosphate rock to crushers, mills, or storage silos.

-Chemical Industry: Handling phosphate rock in the production of phosphoric acid and other chemicals.

-Agriculture: Transporting phosphate rock for soil amendment and fertilizer blending.

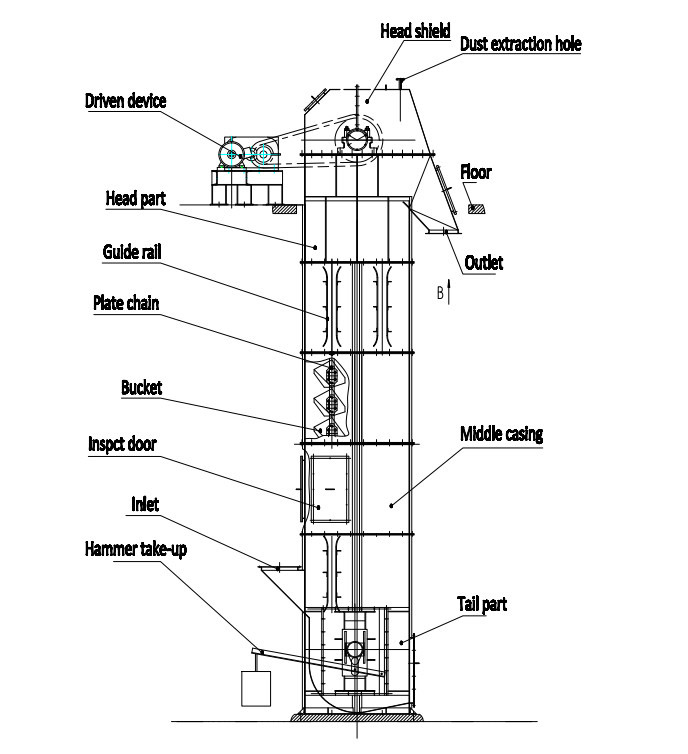

How does the Phosphate Rock Bucket Elevator work?

1.Loading: Phosphate rock is fed into the elevator's boot (bottom section) through an inlet.

2.Lifting: Buckets attached to a belt or chain scoop up the material and carry it upward.

3.Discharge: At the top, the buckets tip over, and the phosphate rock is discharged through an outlet.

4.Return: Empty buckets return to the bottom to repeat the cycle.

Phosphate Rock Bucket Elevator Parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

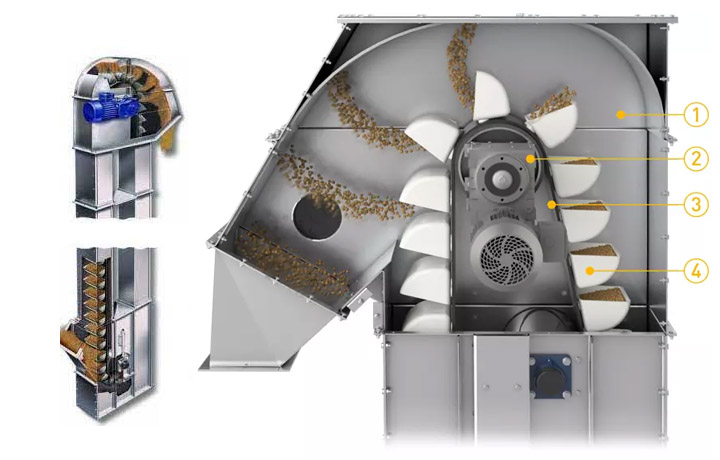

Structure of a Phosphate Rock Bucket Elevator

-Buckets: Made of durable materials like steel or polyethylene to handle abrasive phosphate rock.

-Belt or Chain: Provides the driving force to move the buckets.

-Drive Unit: Includes a motor, gearbox, and pulley/sprocket to power the system.

-Casing: Enclosed structure to prevent dust and material spillage.

-Inlet and Outlet: For loading and discharging phosphate rock.

Advantages of Using a Phosphate Rock Bucket Elevator

-Efficient Material Handling: Transports large quantities of phosphate rock quickly.

-Space-Saving: Vertical design minimizes floor space requirements.

-Cost-Effective: Reduces labor and operational costs.

-Reliable Performance: Ensures consistent and uninterrupted material flow.

-Environmental Protection: Enclosed design reduces dust emissions.

Phosphate Rock Bucket Elevator Customer Case

| Application scenario | Lift height | Lift capacity | Equipment type |

| Used to transport crushed phosphate rock powder from the ground to a 30-meter-high storage bin for subsequent grinding and chemical processing. | 30 meters | 120 tons/hour | TD type belt bucket elevator, using high-strength conveyor belt, suitable for powdery materials, wear-resistant design |

| In the phosphate ore concentrator, granular phosphate ore (5-20mm) is lifted from the crushing workshop to the drying equipment, and the temperature requirement is ≤150℃. | 25 meters | 80 tons/hour | Chain bucket elevator, using high-temperature resistant chain, suitable for high-temperature material transportation |

| Before mixing the phosphate sand with the additive, it is transported to the mixer feed port through the bucket elevator to ensure continuous production. | 15m | 60t/h | Centrifugal unloading bucket elevator for medium-height, high-throughput granular materials |

| In the phosphate beneficiation process, the crushed phosphate ore (10-50mm) is lifted to the vibrating screening equipment for classification. | 40m | 150t/h | High-strength round chain bucket elevator, in accordance with international standard JB3926-85, suitable for heavy ore lifting |

How to Choose a Phosphate Rock Bucket Elevator?

When selecting a phosphate rock bucket elevator, consider the following factors:

Phosphate Rock Material Characteristics

Particle size/shape: Determines the hopper type and discharge method.

Bulk density: Affects conveying capacity and motor power.

Flowability/abrasiveness/humidity/temperature: Determines special structure and material requirements.

Lift Height

Low lifting height (H < 20m): Select small belt or chain bucket elevators, such as TD belt bucket elevator, TH chain bucket elevator, etc.

Medium lifting height (20m ≤ H ≤ 50m): Select medium chain or belt bucket elevators, such as TH, HL chain bucket elevators, or TD belt bucket elevators with larger belt width.

High lifting height (H > 50m): Select high-strength chain or wire rope belt bucket elevators, such as HL, NE plate chain bucket elevators, etc. For higher lifting heights, special designs may be required.

Bucket Type: Choose between centrifugal or continuous discharge buckets.

Construction Material: Select materials resistant to abrasion and corrosion.

Power Requirements: Motor size and energy efficiency.

What is the price of Phosphate Rock Bucket Elevator?

The price of a phosphate rock bucket elevator depends on factors such as:

-Capacity and Size: Larger elevators with higher capacities cost more.

-Material and Build Quality: Stainless steel or specialized coatings increase costs.

-Customization: Additional features like dust control or automation add to the price.

-Brand and Supplier: Prices vary based on the manufacturer and region.

Generally, prices range from$5,000 to $50,000+, depending on the specifications and customization.