NE Plate Chain Bucket Elevator

The plate chain is used as the traction device to lift the material vertically from a low place to a high place.

| Model | NE15, NE30, NE50, NE150, NE200, NE300, NE400, NE500, NE600, NE800. |

| Hopper Type | Deep Hopper or Shallow Hopper |

| Hopper speed | 1.4-2m/s |

| Conveying capacity | 200t/h |

| Height | 60m |

What is the NE Platen Chain Bucket Elevator?

NE Plate Chain Bucket Elevator adopts high-strength wear-resistant plate chain design, which can be used to lift bulk materials such as powder, granular and small blocks from low to high. As an efficient and energy-saving vertical transportation solution, NE series elevators are particularly suitable for continuous lifting of medium, large and abrasive materials, such as limestone, cement clinker, gypsum and lump coal, etc. The material temperature can be as high as 250℃

What types of NE Plate Chain Bucket Elevator are there?

The NE chain bucket elevator series offers a comprehensive range of models suitable for almost all industrial applications requiring vertical material transport, carefully categorized by lifting capacity and structural configuration, which can be selected according to material properties and lifting volume:

NE15, NE30, NE50: For small conveying volumes (15-50 m³/h).

NE150, NE200, NE300: For medium conveying volumes (100-300 m³/h).

NE400, NE500, NE600, NE800: For large conveying volumes (400-800 m³/h).

Each model directly refers to its theoretical maximum handling capacity (m³/h) under optimal conditions. For example, the NE150 can handle up to 150 m³/h, while the NE800 can handle up to 800 m³/h. However, the actual handling capacity may vary depending on material characteristics, lifting height and operating parameters.

Besides the basic capacity differences, NE chain bucket elevators can be classified according to their construction and discharge method:

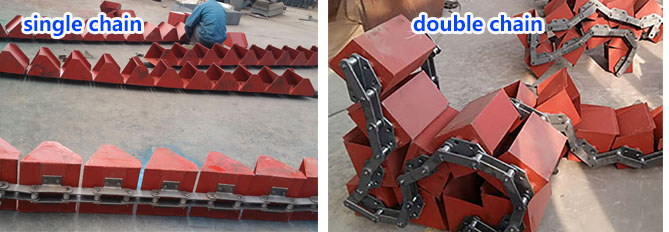

By chain arrangement: single chain (NE15 to NE30 models for lighter loads) and double chain (NE50 to NE800 models standard for increased stability and load distribution)

By discharge method: gravity discharge (standard, material flows out naturally at the head) and centrifugal discharge (optional design for certain materials requiring forced discharge).

What are the advantages of NE Plate Chain Bucket Elevator?

1. The inflow feeding is adopted, so that there is little extrusion and collision between the various parts of the conveyor and the material, the operation is stable, and the maintenance is convenient.

2. The conveyor chain adopts the surface contact of the plate chain, instead of the point connection of the traditional bucket lift chain, so that the service life is improved, and the service life of the conveyor chain can reach more than five years.

3. Due to the adoption of inflow feeding, gravity-induced discharge, low bucket line speed (15-30m/min), and no return phenomenon, the power is only about 40% of that of ordinary chain bucket elevators.

4. The operation rate is high, and the trouble-free operation can reach more than 30,000 hours.

5. Large conveying capacity, the range of conveying is 15-800m3/h.

How does the NE Plate Chain Bucket Elevator work?

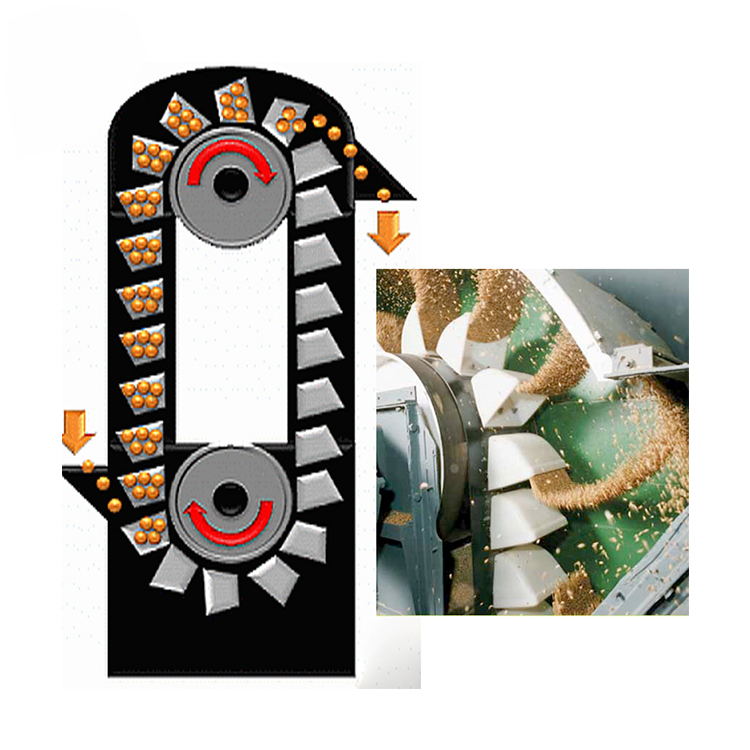

The material enters the running hopper through the feed port, the motor drives the reducer to drive the head sprocket to rotate, and the plate chain pulls the hopper upward; at the head, the material is discharged from the hopper under the action of centrifugal force and gravity, and discharged through the discharge port; the empty hopper returns downward under the guidance of the tail sprocket for the next loading.

NE Plate Chain Bucket Elevator Parameters

| Model | Lifting capacity(m3/h) | Max granularity(mm) | ||||

| maximum percent(%) | ||||||

| 10 | 25 | 50 | 75 | 100 | ||

| NE15 | <16 | <65 | <50 | <40 | <30 | <25 |

| NE30 | <31 | <90 | <75 | <58 | <47 | <40 |

| NE50 | <60 | <90 | <75 | <58 | <47 | <40 |

| NE100 | <110 | <130 | <105 | <80 | <65 | <55 |

| NE150 | <165 | <130 | <105 | <80 | <65 | <70 |

| NE200 | <220 | <170 | <135 | <100 | <85 | <70 |

| NE300 | <320 | <170 | <135 | <100 | <85 | <70 |

| NE400 | <441 | <250 | <165 | <125 | <105 | <90 |

| NE500 | <470 | <240 | <190 | <145 | <120 | <100 |

| NE600 | <600 | <240 | <190 | <145 | <120 | <100 |

| NE800 | <800 | <275 | <220 | <165 | <135 | <100 |

NE Plate Chain Bucket Elevator Options

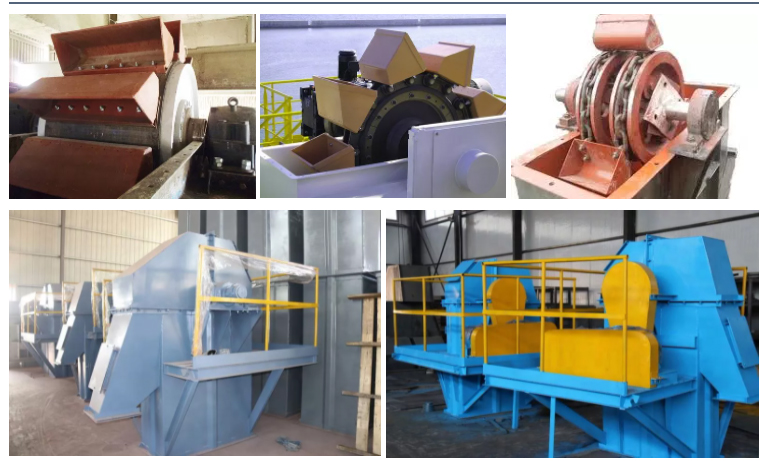

1. Upper device: installed with track (double row) to prevent the chain from swinging, backstop to prevent the hopper from rotating, the material blocks the lower casing, and the discharge port is equipped with a rubber plate to prevent the material from returning.

2. Intermediate section: Some intermediate sections are equipped with tracks (double-row sections) to prevent the chain from swinging during operation, and some intermediate sections are equipped with access doors for maintenance.

3. Lower device: installed with tensioning device, NE15~NE50 adopts spring tensioning, NE100~NE800 adopts heavy hammer box tensioning.

4. The upper and lower sprockets adopt ZG310-570. Overall quenching and tempering, HB229-269 tooth surface quenching HRC40~48.

5. Plate chain: the chain plate adopts 45 # HRC36~42, and the plate chain elevator chain adopts the high-strength wear-resistant chain processed from alloy steel by advanced heat treatment methods. Under normal continuous use, the service life of the conveyor chain can be guaranteed 3-5 year.

What are the applications of NE Plate Chain Bucket Elevator?

NE plate chain bucket elevator is mainly suitable for conveying raw materials, cement, coal, coke, limestone, dry clay, clinker, gravel, sandstone, fertilizer, grain and other powder, granular, small block grinding or non-grinding materials. The plate chain bucket elevator scoops up the material in the hopper from the storage place, lifts it up with a chain, turns down around the top wheel, and sends the material into the acceptance slot. The chain drive of the bucket elevator is generally equipped with two parallel transmission chains. , There is a pair of transmission sprockets on the top or bottom, and a series of sprockets on the bottom or the top.

NE Plate Chain Bucket Elevator Customer Case

Clinker conveying system of a large cement plant: The cement plant uses multiple NE series plate chain bucket elevators to transport the crushed cement clinker from the crushing workshop to the clinker storage. With its powerful conveying capacity and stable operating performance, the NE series elevator ensures the continuous and efficient operation of the production line and significantly improves production efficiency.

Raw coal lifting system of a coal mine: The coal mine uses NE series plate chain bucket elevators for vertical lifting of raw coal. Since raw coal has a certain blockiness and abrasiveness, the NE series elevator effectively solves the problem of easy damage of the belt elevator with its high-strength plate chain and wear-resistant bucket, ensuring safe and reliable material transportation.