Mineral Powder Conveying Bucket Elevator

Equipment specially used for vertical conveying of fine particles or powdered materials such as mineral powder, lime powder, cement powder, coal powder, etc.

Conveying capacity: 10-800 m³/h

Bucket height: 1-50 m

Bucket speed: 0.5-3 m/s

Bucket spacing: 150-500 mm

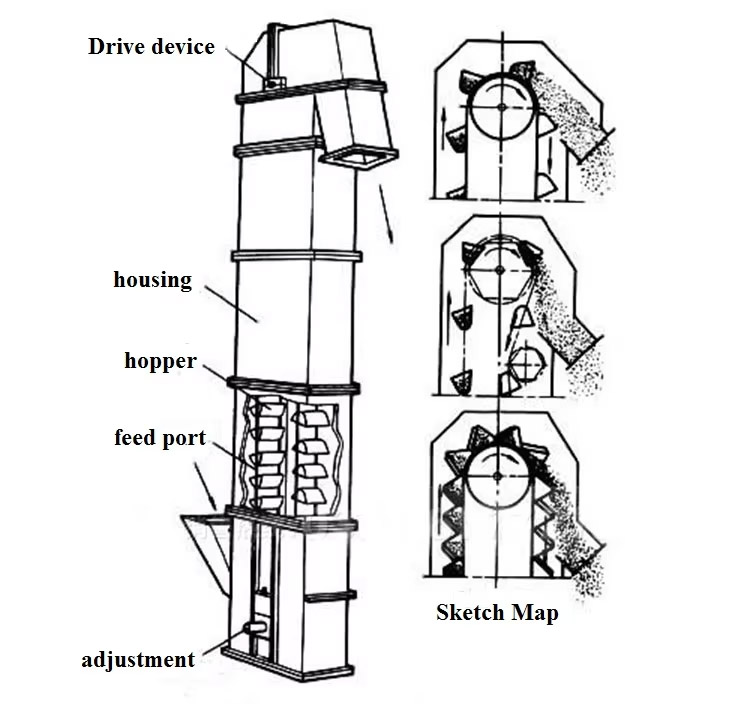

What is a Mineral Powder Conveying Bucket Elevator?

Mineral Powder Conveying Bucket Elevator is a highly efficient vertical conveying equipment, specially used for conveying fine particles or powdered materials such as mineral powder, lime powder, cement powder, coal powder, etc. It lifts materials from low to high through evenly distributed hoppers, and is suitable for gravity unloading or centrifugal unloading.

What applications can the Mineral Powder Conveying Bucket Elevator be used for?

This equipment is mainly used for vertical conveying of powdered, granular and small block materials, and is suitable for the following scenarios:

Mineral powder conveying (such as iron ore powder, copper ore powder, aluminum ore powder, etc.)

Powder conveying in cement, lime and other building materials industries

Coal powder conveying (such as power plant, boiler fuel conveying)

Chemical powder material conveying (such as alumina powder, silicon powder, etc.)

Grain and feed industry (such as flour, starch, etc.)

How does the Mineral Powder Conveying Bucket Elevator work?

1. Material feeding: powdered materials enter the hopper through the feed port.

2. Hopper lifting: the hopper is evenly distributed on the ring traction chain or belt, and the material is lifted from the bottom to the top as the equipment runs.

3. Discharging method:

Gravity unloading: suitable for slow conveying, the material slides to the discharge port by its own gravity.

Centrifugal unloading: suitable for high-speed conveying, the material is thrown out to the discharge port during high-speed operation.

4. Circulation operation: the equipment operates continuously to achieve stable conveying of powder.

What are the advantages of Mineral Powder Conveying Bucket Elevator?

High conveying height: up to tens of meters, suitable for high-rise conveying.

Good sealing performance: reduce dust flying, good environmental performance.

Strong conveying capacity: can continuously convey a large amount of powder materials.

Compact structure: small footprint, suitable for small spaces.

Low energy consumption: lower power consumption compared to other conveying methods.

Wear-resistant and durable: made of wear-resistant materials, long service life.

Mineral Powder Conveying Bucket Elevator Parameters

| Model | TH300 | TH400 | TH315 | TH400 | TH500 | TH630 | TH800 | ||||||||

| Bucket form | Q | S | Q | S | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh | Zh | Sh | |

| Capacity(m3/h) | 24 | 28 | 45 | 47 | 21 | 36 | 36 | 56 | 45 | 70 | 68 | 110 | 87 | 141 | |

| Bucket width(mm) | 300 | 400 | 315 | 400 | 500 | 630 | 800 | ||||||||

| Bucket volume (L) | 4.4 | 5.2 | 10 | 10.5 | 3.75 | 6 | 5.9 | 9.5 | 9.3 | 15 | 14.6 | 23.6 | 23.3 | 37.5 | |

| Pitch of buckets(mm) | 512 | 512 | 512 | 512 | 688 | 688 | 920 | ||||||||

| Chain specification | Φ18×64 | Φ18×64 | Φ18×64 | Φ18×64 | Φ22×86 | Φ22×86 | Φ26×92 | ||||||||

| Sprocket pitch diameter(mm) | 630 | 630 | 630 | 710 | 800 | 900 | 1000 | ||||||||

| Bucket speed(m/s) | 1.4 | 1.4 | 1.4 | 1.4 | 1.5 | 1.5 | 1.6 | ||||||||

| The maximum size of material(mm) | 40 | 50 | 45 | 55 | 65 | 75 | 85 | ||||||||

Mineral Powder Conveying Bucket Elevator Customer Use Site

| Application Scenario | Material Characteristics | Lifting Amount | Lifting Height | Equipment Selection |

| Raw Material Powder Conveyed into Preheater of a 5000t/d Cement Production Line | Limestone Powder (Density 1.2t/m³, Moisture Content <1%) | 280t/h | 42.5m | NE200 plate chain bucket elevator (bucket width: 200mm; chain specification: 18×64-FU; explosion-proof design (ATEX certification)) |

| Enclosed transportation of coal powder from mill to blast furnace coal powder bin | Coal powder (particle size 200 mesh, explosive dust) | 50t/h | 28m | TGD wire belt bucket elevator (nitrogen protection system (oxygen content <8%); temperature/spark monitoring interlock; anti-static tape, (surface resistance <10⁶Ω)) |

| 325 mesh quartz powder transportation from classifier to finished product bin | Quartz powder (Mohs hardness 7, strong abrasiveness) | 80t/h | 15m | TH315 chain bucket elevator, hopper sprayed with tungsten carbide (thickness 2mm), alloy steel carburizing treatment, dustproof level: IP65 |

How to select Mineral Powder Conveying Bucket Elevator?

When choosing a suitable bucket elevator, the following factors need to be considered:

1. Material characteristics:

Is the material sticky?

Is the material easy to absorb moisture and agglomerate?

Specific gravity, particle size, and temperature of the material?

2. Conveying capacity:

How many tons/hour do you need to convey?

The height you need to lift?

3. Working environment:

Is explosion-proof design required (such as coal powder conveying)?

Is a high temperature resistant design required (such as cement clinker conveying)?

4. Drive mode:

Belt drive is suitable for general materials and has a lower cost.

Chain drive is suitable for heavy loads and high temperature materials and has greater durability.

5. Discharge mode:

Low speed conveying is suitable for gravity discharge.

High speed conveying is suitable for centrifugal discharge.

6. Maintenance requirements:

Is a convenient inspection port required?

Is the equipment easy to replace the hopper and chain?

Phosphate rock bucket elevator

Phosphate rock bucket elevator Chemical Raw Material Bucket Elevator

Chemical Raw Material Bucket Elevator