Grain Bucket Elevator

Lift various grains vertically from a low place to a designated location

| Lifting height | 60 meters |

| Conveying capacity | 5-100m³/hour |

| Hopper capacity | 0.5-9L |

| Hopper spacing | 280-625mm |

| Operation speed | 1.4-2.2m/s |

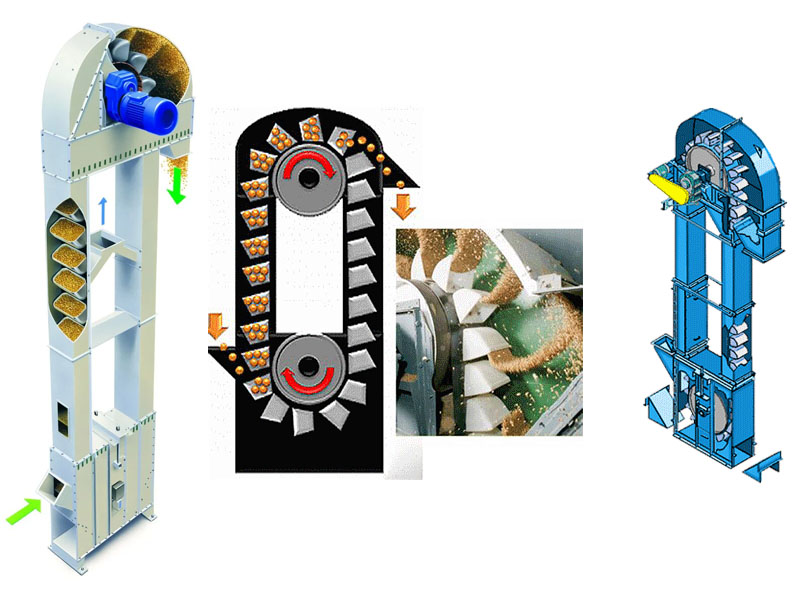

What is Grain Bucket Elevator?

Grain Bucket Elevator is specially designed for vertical conveying systems of various grains in agricultural, milling and storage facilities. Grains such as wheat, corn, rice, barley, soybeans, etc. are lifted from low to high through continuous hoppers to achieve efficient material transportation. It is widely used in grain processing plants, granaries, feed mills, flour mills and other places.

Our Grain Bucket Elevator combines sturdy structure with advanced engineering technology to provide a reliable, efficient and cost-effective solution for vertically conveying grain with minimal damage and maximum throughput.

What types of Grain Bucket Elevators are there?

Centrifugal Discharge Elevators: Ideal for fine grains like wheat flour and corn meal, operating at higher speeds for efficient discharge

Continuous Bucket Elevators: Designed for fragile or abrasive grains, featuring closely spaced buckets that gently handle materials

Stainless Steel Models: Food-grade elevators for grain processing facilities with strict hygiene requirements

Heavy-Duty Chain Elevators: For tough applications with large grain volumes or long vertical lifts

Why use bucket elevators for conveying grain?

Compared with traditional equipment such as screw conveyors and belt conveyors, bucket elevators have obvious advantages in vertical transportation:

Higher conveying height: up to 60 meters, suitable for multi-story buildings or high-level storage.

Less grain damage: hopper design, flexible conveying method, reduce grain breakage, maintain quality.

Smaller floor space: vertical structure design, saves ground space, strong adaptability.

Lower energy consumption: efficient conveying method, reduce energy consumption, save costs.

How does the grain bucket elevator work?

Grain Bucket Elevator uses hoppers evenly arranged on the traction member to lift grains from the lower feed port to the upper discharge port. Driven by the drive device, the hopper runs along the closed shell to complete the continuous conveying of grains. The grains are subjected to less impact and friction during the lifting process, effectively maintaining the integrity of the grains.

Grain bucket elevator parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

All sizes can be designed, adjusted and manufactured to suit vertical packaging and meet the warehousing needs of grain businesses.

What is the purpose of a grain bucket elevator?

Grain Bucket Elevator is a mechanical equipment specially used for vertical conveying of various bulk grains. Its main uses include:

Agricultural production link: lifting harvested grains (such as wheat, corn, rice, soybeans, etc.) from the ground to granaries, drying equipment, processing equipment, etc.

Grain storage link: used for grain transfer, warehousing and outbound operations between granaries to improve storage efficiency.

Grain processing link: transporting grains from one production link to the next, such as from cleaning equipment to grinding equipment, or from crushing equipment to packaging equipment.

Feed production link: used to transport feed raw materials such as corn and soybean meal.

Port terminal: used for loading and unloading ships of bulk grains.

Grain Bucket Elevator Customer Case

| Customer name | Application scenario | Conveying material | Conveying capacity (m/h) | Lifting height (m) |

| A grain processing plant | Wheat cleaning workshop | Wheat | 30 | 25 |

| A feed production enterprise | Feed raw material transportation | Corn | 45 | 30 |

| A grain warehouse | Grain storage and transportation | Rice | 50 | 35 |

| A certain subsidiary | Seed processing workshop | Various seeds | 20 | 20 |

| A food processing plant | Food raw material transportation | Flour | 25 | 15 |

Sugar Bucket Elevator

Sugar Bucket Elevator Food Grade Bucket Elevator

Food Grade Bucket Elevator