Gangue bucket elevator

It is a kind of equipment used for vertical transportation of coal gangue.

| Lifting height | 10-100 m, Can be customized according to needs |

| Conveying capacity | 10-500 t/h |

| Hopper capacity | 5-50 L |

| Motor power | 5.5-75 kW |

| Operating speed | 0.8-3.5 m/s |

What is gangue bucket elevator?

Gangue bucket elevator is a kind of equipment specially used for vertical transportation of bulk materials such as gangue, ore, coal, etc. It lifts materials from low to high through a hopper fixed on a chain or belt, and is widely used in mining, metallurgy, building materials and other industries.

What are the functions of gangue bucket elevator?

Vertical transportation: Efficiently lift bulk materials such as gangue from low to high.

Large-capacity transportation: Suitable for large-tonnage and ultra-high-altitude material transmission, with large lifting capacity.

Good sealing performance: Reduce dust pollution and improve the working environment.

Strong wear resistance: Use high manganese steel or polymer wear-resistant lining to extend the life of the equipment.

Safe and reliable: Equipped with safety devices such as speed, deviation, blockage and temperature detection to ensure stable operation.

What are the applications of gangue bucket elevator?

Mining industry: Used for vertical transportation of gangue, ore and coal.

Metallurgical industry: Transport metallurgical raw materials and waste.

Building materials industry: used for lifting cement, limestone and other materials.

Ports and docks: used for loading, unloading and transshipment of bulk materials.

Energy industry: transporting coal and ash in thermal power plants.

Gangue bucket elevator customer cases

| Application Scenario | Capacity | Lifting Heights | Features |

| Vertical lifting of coal gangue from underground mining to surface disposal. | 80-100 tons/hour | 25 meters | Heavy-duty chain design, wear-resistant buckets for abrasive gangue material |

| A Power Plant Gangue Handling in the Philippines: Transporting combustible gangue to boiler feed systems in a coal-fired power plant. | 120-150 tons/hour | 30 meters | High-temperature resistant buckets, explosion-proof motor for safety. |

| A European Cement Plant Raw Material Transport: Feeding gangue-based raw mix into cement kilns for clinker production. | 60-80 tons/hour | 20 meters | Dust-proof sealing, corrosion-resistant stainless steel buckets. |

| Waste recycling facility (Germany): sorting and lifting mining waste gangue for reuse in construction materials. | 40-60 tons/hour | 15 meters | Modular design, energy-efficient drive system. |

How does gangue bucket elevator work?

When Gangue Bucket Elevator is working, Gangue enters the hopper from the bottom feed port, and the hopper is driven by a chain or belt to lift the gangue to the top; it is unloaded at the top by centrifugal force or gravity, and the empty hopper returns to the bottom to complete a cycle.

Gangue bucket elevator parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

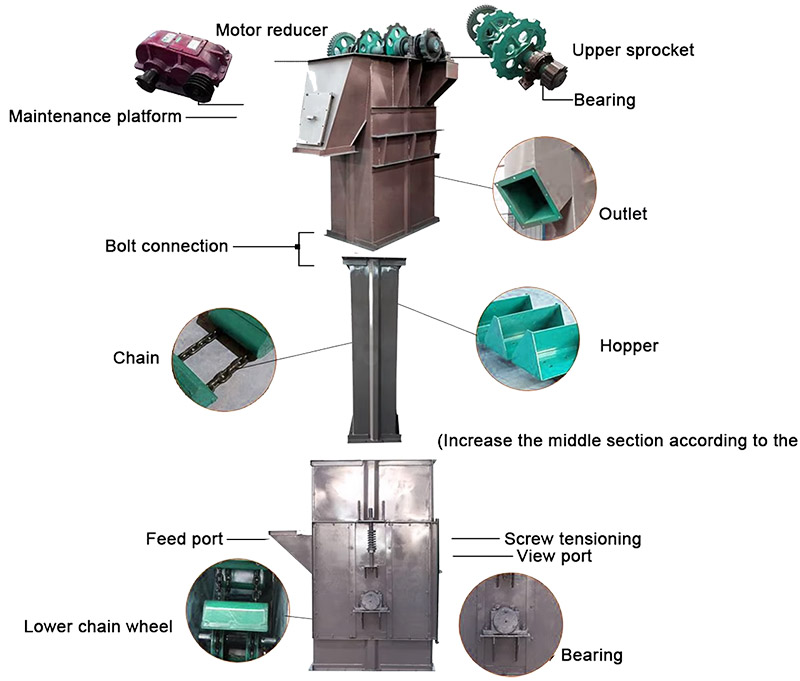

What are the structures of gangue bucket elevator?

Head device: including drive wheel, backstop and discharge port.

Tail device: including tension wheel and self-cleaning structure to prevent material adhesion.

Hopper: high-strength plastic or iron hopper, wear-resistant and large capacity.

Chain or belt: used to fix and drive the hopper.

Casing: sealed design to reduce dust leakage.

How to select Gangue Bucket Elevator?

Gangue Characteristics (Abrasiveness and Moisture)

High Abrasiveness: Gangue (coal/mining waste) is abrasive and requires wear-resistant materials (e.g. NM400 steel buckets, manganese steel chains) to reduce maintenance.

Moisture Content: Wet gangue may stick to buckets; choose perforated buckets or anti-fouling coatings to prevent material buildup.

Lift Height and Capacity

Height: Choose a lift with a lift range of 20-50m for typical gangue transport (e.g. coal mines, power plants)1. Higher lifts (>50m) may require reinforced chains.

Capacity: Small: 10-50 T/H (e.g. recycling plants); Industrial: 80-150 T/H (e.g. cement plants, coal processing).

Material and Durability

Bucket/Chain: Stainless steel (food grade applications) or hardened steel (mining/cement) for corrosion/wear resistance.

Frame: Carbon steel with anti-corrosion paint for harsh environments.

Bucket Type

Deep bucket: For fine/powdered gangue (e.g., coal ash).

Shallow bucket: For lumpy gangue (e.g., mining waste).

Perforated bucket: For wet gangue to facilitate drainage.

Power and drive system

Motor: 5.5–30 kW, depending on load and speed. Variable frequency drive (VFD) adjusts speed for different gangue loads.

Drive: Chain drive: Heavy duty (e.g., mining), high torque; Belt drive: Low maintenance for light loads.