Fertilizer Conveying Bucket Elevator

Vertical conveying equipment designed for powdered or granular fertilizers, with high efficiency, good sealing, large conveying capacity, industrial equipment solutions

Conveying capacity: 15-1550 m³/h

Lifting height: 75 meters

Operating speed: 0.5 -1.5 m/s

Bucket capacity: 2.5-23.6 L, bucket distance: 203.2-882 mm

What is Fertilizer Conveying Bucket Elevator?

Fertilizer Conveying Bucket Elevator is a mechanical equipment used for vertical or inclined conveying of fertilizers. It transports fertilizers from low places to high places through a bucket-type lifting structure. It is widely used in fertilizer production, storage and packaging, and is efficient, stable and durable.

Why use Bucket Elevator to transport Fertilizer?

1. Improve efficiency: quickly transport fertilizers from the ground to high places to reduce manual handling costs.

2. Save space: The vertical design reduces the floor space and is suitable for factories with limited space.

3. Protect materials: The closed structure prevents fertilizers from getting damp, contaminated or spilled.

4. Automated production: seamlessly connected with the production line to achieve continuous and automated operations.

What industries can Fertilizer Conveying Bucket Elevator be used in?

1. Fertilizer production: used for raw material lifting and finished product transportation.

2. Agriculture: used for fertilizer storage and distribution.

3. Warehousing logistics: used for loading, unloading and stacking of fertilizer warehouses.

4. Environmental protection industry: used for the transportation and processing of organic fertilizers.

What are the advantages of Fertilizer Conveying Bucket Elevator?

1. Efficient transportation: The transportation volume can reach 10-100 tons per hour to meet the needs of different scales.

2. Strong durability: Use wear-resistant materials to adapt to the corrosiveness and abrasion of fertilizers.

3. Closed design: Prevent dust from spilling, environmentally friendly and safe.

4. Flexible configuration: height, bucket capacity and drive mode can be customized according to needs.

5. Low energy consumption: stable operation, low energy consumption and cost saving.

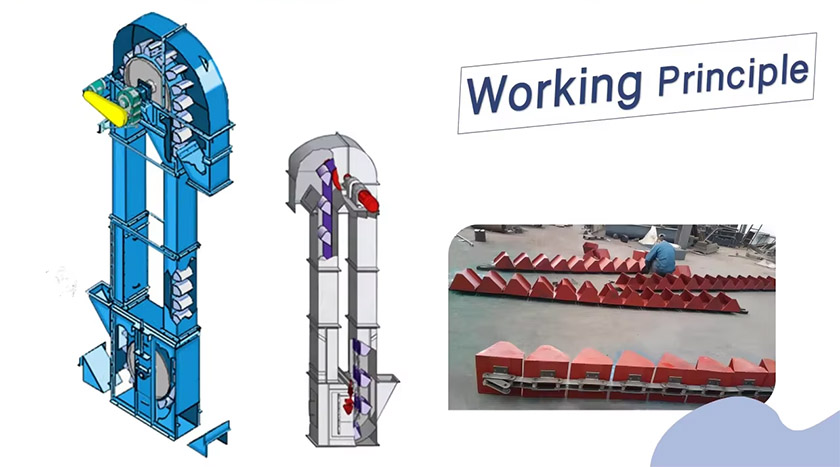

What is the principle of fertilizer conveying bucket elevator?

1. Feeding: Fertilizer enters the bucket through the bottom feed port.

2. Lifting: The drive device drives the chain or belt, and the bucket is lifted in a vertical or inclined direction.

3. Unloading: After the bucket reaches the top, the fertilizer is discharged by gravity or centrifugal force.

4. Return: The empty bucket returns to the bottom along the return track to complete the cycle.

Fertilizer Conveying Bucket Elevator Parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

What are the components of the Fertilizer Conveying Bucket Elevator?

1. Head: drive device, discharge port, head roller.

2. Tail: feed port, tail roller, tensioning device.

3. Bucket: made of wear-resistant material, fixed on chain or belt.

4. Chain/belt: carries bucket and transmits power.

5. Casing: closed design to prevent dust from spilling.

6. Support structure: columns and beams to ensure the stability of the equipment.

Fertilizer Conveying Bucket Elevator Customer Cases

| Cases | Application | Lifting Height | Capacity | Key Features |

| NPK Fertilizer Plant (Large-Scale Production) | Vertical transport of blended NPK granules to packaging line | 25m (from mixing to silo storage) | 50 tons/hour | Abrasion-resistant steel buckets; Dust-proof sealed design; Automatic lubrication system |

| Organic Compost Facility (Eco-Friendly Operation) | Lifting fermented organic fertilizer to drying system | 15m | 30 tons/hour | Corrosion-resistant coating; Gentle handling to maintain granule integrity; Easy-clean design for organic material |

| Urea Granule Storage (High-Capacity Handling) | Transporting urea from production line to storage silos | 40m | 80 tons/hour | Explosion-proof motor (for urea dust safety); Heavy-duty chain drive system; Moisture-proof construction |

How to Select Fertilizer Conveying Bucket Elevator?

1. Fertilizer Properties (Material Characteristics)

| Fertilizer Type | Key Considerations | Recommended Bucket Elevator Features |

| NPK/Granular Fertilizers | Abrasive, may cause wear | Wear-resistant steel buckets & chains |

| Urea/Ammonium Nitrate | Hygroscopic, may clump | Sealed design, anti-corrosion coating |

| Organic/Compost Fertilizers | Sticky, may clog | Self-cleaning buckets, wider spacing |

| Powdered Fertilizers | Dusty, may explode | Explosion-proof motor, dust-proof casing |

2. Lifting Height (Vertical Transport Distance)

| Height Range | Recommended Bucket Elevator Type | Applications |

| < 15m | Light-duty, belt-driven | Small farms, packaging lines |

| 15m - 30m | Medium-duty, chain-driven | Blending plants, mid-sized storage |

| > 30m | Heavy-duty, reinforced chains | Large silos, industrial fertilizer plants |

3. Capacity (Tons per Hour, t/h)

| Capacity (t/h) | Bucket Size & Speed | Suitable Fertilizer Types |

| 5 - 20 t/h | Small buckets, moderate speed | Organic compost, small-scale production |

| 20 - 50 t/h | Medium buckets, higher speed | NPK granules, mid-sized plants |

| 50 - 100+ t/h | Large buckets, high-speed | Urea, large-scale fertilizer factories |

4. Material & Durability (Construction & Protection)

| Component | Material Options | Best For |

| Buckets | Polyethylene (PE), Steel, Stainless Steel | PE for corrosion resistance, steel for abrasion |

| Chains/Belts | Rubber belt, steel chain, nylon-coated | Rubber for light-duty, steel for heavy-duty |

| Casing | Galvanized steel, stainless steel, carbon steel | Stainless for corrosive environments |

5. Additional Features (Customization Options)

Dust-Proof Design — Essential for powdered fertilizers (e.g., DAP, MAP).

Explosion-Proof Motor — Required for urea/ammonium nitrate handling.

Automatic Lubrication — Reduces maintenance for high-capacity elevators.

Variable Speed Drive — Adjustable for different fertilizer types.

Selection Summary Table

| Factor | Key Questions | Recommendation |

| Fertilizer Type | Is it granular, powdery, or sticky? | Choose bucket spacing & material accordingly |

| Lifting Height | How high does it need to go? | Belt (short) vs. chain (long) |

| Capacity | How many tons per hour? | Larger buckets & faster speed for high volume |

| Material Durability | Is it abrasive or corrosive? | Stainless steel for corrosion, hardened steel for wear |

| Safety Requirements | Is dust or explosion a risk? | Explosion-proof & dust-proof options |

By evaluating these factors, you can select the optimal bucket elevator for your fertilizer handling needs. Consult manufacturers for custom solutions based on specific requirements.

What is the maintenance of fertilizer conveying bucket elevator?

1. Regular inspection: Check the tension and wear of the chain/belt, and adjust or replace it in time.

2. Lubrication maintenance: Regularly add lubricating oil to moving parts such as bearings and chains to reduce wear.

3. Clean up the accumulated materials: Regularly clean the residual materials in the bucket and casing to prevent blockage.

4. Check the motor: Ensure that the motor is running normally to avoid overheating or overloading.

5. Anti-rust treatment: Anti-rust treatment is performed on the outer surface of the equipment to extend its service life.

6. Safety protection: Regularly check whether the safety devices (such as emergency stop switches and protective covers) are normal.