Feed Bucket Elevator

Saturday May-24 2025 14:50:05

Feed bucket elevator is a vertical conveying equipment specially designed for the feed industry. It continuously lifts powdered, granular or small-block feed materials from a low place to a high place through a series of hoppers fixed on belts or chains. In the feed processing process, bucket elevators undertake important tasks such as raw material reception, intermediate process transfer and lifting before finished product packaging. It is a "vertical bridge" connecting various processes and is commonly used in animal husbandry and feed processing industries.

Compared with traditional conveying equipment, feed bucket elevator has significant advantages such as small footprint, high conveying efficiency, low energy consumption, and good sealing. Modern feed bucket elevator adopts modular design, and the lifting height can be flexibly adjusted according to the actual needs of the factory, ranging from 3 meters to 60 meters, to meet the needs of feed factories of different sizes.

In feed production, the materials that bucket elevators can handle include but are not limited to:

Cereals: corn, wheat, barley and other raw materials

Proteins: soybean meal, fish meal, meat and bone meal, etc.

Additives: vitamin premixes, minerals, enzyme preparations, etc.

Finished feed: pellet feed, powdered feed, crushed feed, etc.

Why choose bucket elevator to convey feed?

High vertical space utilization: Feed mills usually have limited space, and bucket elevators can make full use of vertical space to reduce the site occupation caused by horizontal transportation.

Excellent sealing performance: The fully enclosed structure effectively prevents the leakage of feed dust, which not only ensures a clean production environment, but also avoids the waste of raw materials.

Adapt to a variety of materials: By replacing different types of hoppers, it can handle various feed raw materials and finished products from powder to granular materials.

Energy consumption economy: Compared with pneumatic conveying, the energy consumption of bucket elevators is only 1/10-1/5, which greatly reduces production costs

What are the applications of Bucket Elevator in feed processing?

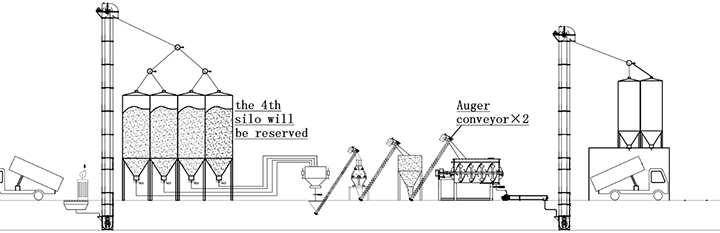

In a complete feed production line, Feed Bucket Elevator mainly undertakes the following key tasks:

Raw material reception and cleaning: lift the grain raw materials unloaded into the pit to the cleaning screen to remove impurities. This section usually requires a large-capacity elevator, such as the TDTG60/30 model, which has a processing capacity of up to 80t/h to meet the needs of fast unloading.

Pre-crushing lifting: lift the cleaned raw materials to the crushing bin above the crusher. This link has high requirements for sealing to prevent dust from escaping.

Batching and mixing system: lift various raw materials to the batching scale, mix them, and then lift them to the granulation bin. Multiple small and medium-sized elevators are often used here for greater flexibility6.

Post-granulation processing: lift the high-temperature pellet feed to the cooler, and then lift it to the grading screen after cooling. The elevator here needs to be resistant to high temperatures, and some models can handle hot pellets above 100°C.

Finished product packaging: lift the finished feed to the packaging bin or bulk distribution bin. This process has high requirements for feed integrity, and a low-speed model should be selected to reduce breakage

How does the feed bucket elevator work?

Bucket design: The buckets on the feed bucket elevator are specially designed to load and convey materials efficiently. These buckets are usually made of wear-resistant materials such as steel or plastic to withstand the weight and wear of the conveyed materials.

Drive mechanism: The elevator is driven by a drive mechanism, usually an electric motor, which provides power to move the buckets on the chain or belt.

Vertical conveying: As the buckets move along the conveyor chain or belt, they load the material from the bottom and convey it to the top. At the discharge port, the material is released into a diversion trough or another conveying device for further processing or storage.

Feed Bucket Elevator Parameters

| Model | Max Feed Size (mm) | Capacity (Ton/Hour) | Lifting Speed (m/s) | Belt Width (mm) | Lifting Height (m) |

| TD160 | 25 | 5.4-16 | 1.4 | 200 | <40 |

| TD250 | 35 | 12-35 | 1.6 | 300 | <40 |

| TD315 | 45 | 17-40 | 1.6 | 400 | <40 |

| TD400 | 55 | 24-66 | 1.8 | 500 | <40 |

| TD500 | 60 | 38-92 | 1.8 | 600 | <40 |

| TD630 | 70 | 85-142 | 2 | 700 | <40 |

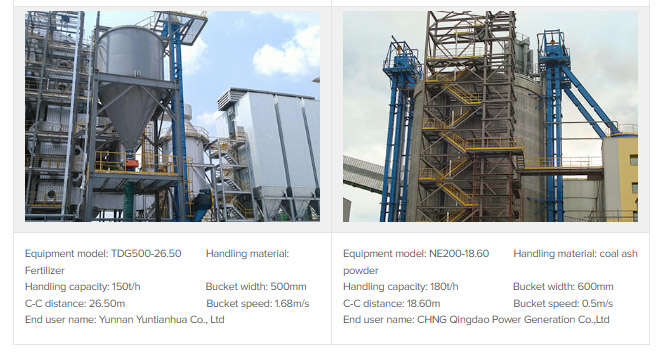

Feed Bucket Elevator Customer Case

Large-scale complete feed plants: with long production lines and large output, usually use multiple large-scale feed bucket elevators in series. For example, in a livestock and poultry feed plant with an output of 50 tons per hour, the main elevators are mostly large-capacity models such as TDTG60/30 or NE50 to ensure smooth production.

Premix plants: with strict requirements on hygiene and cross-contamination control, most use feed bucket elevators with all-stainless steel structures and special seals. The hopper design is also more sophisticated to prevent trace components from remaining.

Aquatic feed plants: because the raw materials are mostly high in protein and fat, the feed bucket elevator needs to strengthen the explosion-proof design and corrosion resistance. Some shrimp feed manufacturers also choose to run at low speed to reduce particle breakage.

How to select a feed bucket elevator?

Material properties: Determine the type of feed (powder/granular feed), bulk density, particle size, humidity, abrasiveness, etc. For highly corrosive feeds such as fish meal, stainless steel should be used.

Production scale and output: Determine the required conveying capacity based on the production line capacity, and consider a margin of about 20% to cope with production fluctuations. For example, a pellet feed production line with an output of 20 tons per hour should choose a model with a conveying capacity of more than 25t/h.

Conveying distance and height: According to the layout and height requirements of the actual production site, select a bucket elevator with a suitable lifting height and conveying distance.

Feed bucket elevator is an important equipment for vertical conveying of bulk materials in various industrial fields. Its reliable operation, efficient material handling capacity and customizable design make it a key tool for improving production efficiency and optimizing material handling processes.