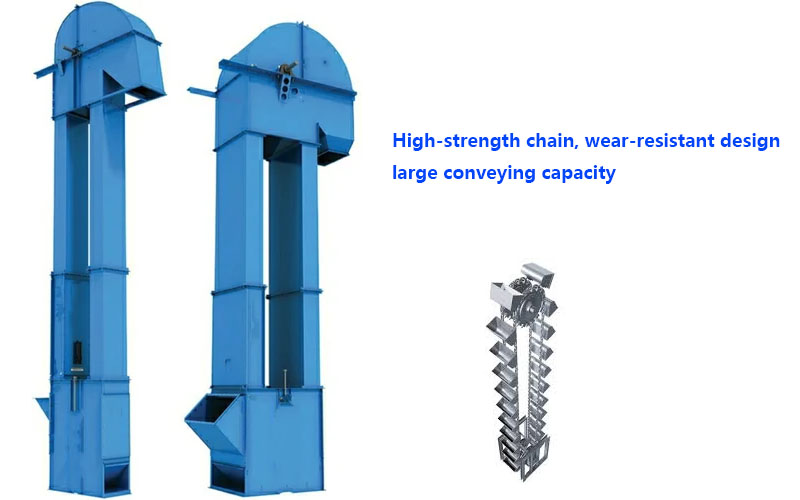

Chain Type Bucket Elevator

The chain drives the hopper to lift the material from the bottom to the top

| Conveyance | 21-220 (m³/h)l |

| Bucket speed | 1.4-1.6 (m/s) |

| Material mass | 45-100 (mm) |

What is Chain Type Bucket Elevator?

Chain Type Bucket Elevator is a high-efficiency vertical conveying equipment that uses high-strength chains as traction components. It is widely used in cement, chemical, mining, grain, metallurgy and other industries to lift powder, granular and small block materials. Compared with traditional belt or chain bucket elevators, chain bucket elevators use plate chain structure, which has higher wear resistance, larger conveying capacity, longer service life, and is particularly suitable for conveying materials with high abrasiveness and high temperature.

What types of Chain Type Bucket Elevator are there?

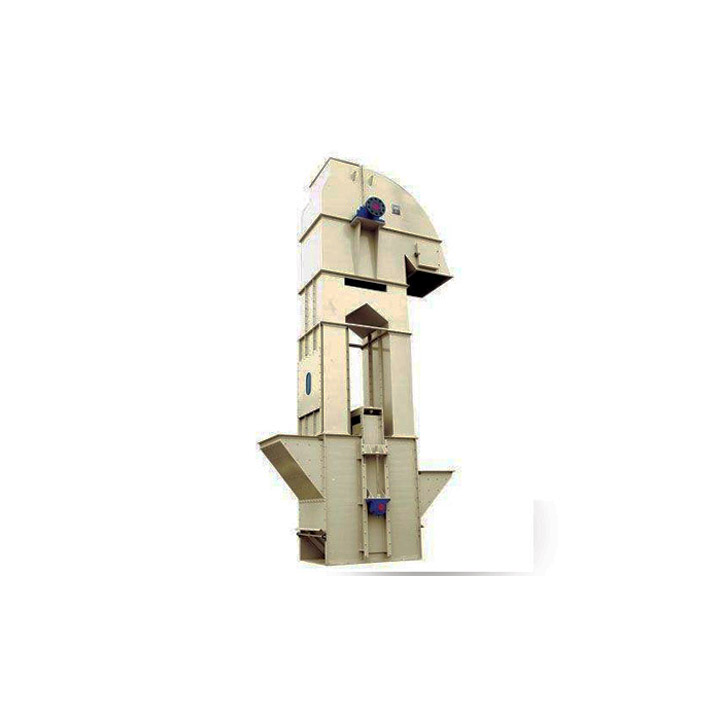

Chain Type Bucket Elevator is divided into NE plate chain, TH ring chain, and ZTD chain according to the chain; it can be divided into gravity and centrifugal unloading according to the structure, and single drive and double drive according to the drive mode, which can be selected according to the lifting material and application scenario.

NE Chain Type Bucket Elevator: It adopts a single high-strength plate chain with excellent wear resistance, suitable for large conveying volume and highly abrasive materials (such as cement and slag).

TH Chain Type Bucket Elevator: It adopts forged ring chain, suitable for medium abrasive materials (such as coal and fertilizer).

ZTD Chain Type Bucket Elevator: It is suitable for grain, chemical and other industries, with simple structure and stable operation.

What are the advantages of Chain Type Bucket Elevator?

Ultra-high wear resistance: It uses precision forged plate chain, and its service life is 2-5 times that of ordinary chains, reducing the frequency of replacement. The sprocket adopts a wear-resistant plate combination design. After wear, only the guard plate needs to be replaced to reduce maintenance costs.

Large conveying capacity & high efficiency: The conveying capacity can reach 15-800 m³/h, which is 1-2 times higher than that of ordinary elevators. The inflow feeding reduces the return material and reduces energy consumption by 40%.

Long life and low maintenance: It uses synthetic lubricants imported from the United States, which only need to be refilled once every 1-2 years. The fully sealed structure reduces dust spillage and extends the life of the equipment.

Strong adaptability: It can lift materials with high abrasiveness and high temperature (≤250℃), such as cement clinker and slag. The special design can be used in offshore or marine environments (need to be customized)

What is the difference between Chain Type Bucket Elevator and ordinary bucket elevator?

| Comparison items | Chain bucket elevator | Ordinary bucket elevator (belt/ring chain) |

| Traction method | High-strength plate chain | Belt/forged ring chain |

| Wear resistance | Extremely high, service life of more than 5 years | Generally, the belt is easy to wear |

| Applicable materials | Abrasive materials (such as slag, cement clinker) | Low abrasive materials (such as grain, coal) |

| Heat resistance | ≤250℃ (short-term 400℃) | ≤60℃ (belt type) or ≤250℃ (chain type) |

| Conveying capacity | 15-800 m³/h (NE series) | 4-600 m³/h |

| Maintenance cost | Low, fewer wearing parts | High, need to replace belts/chains frequently |

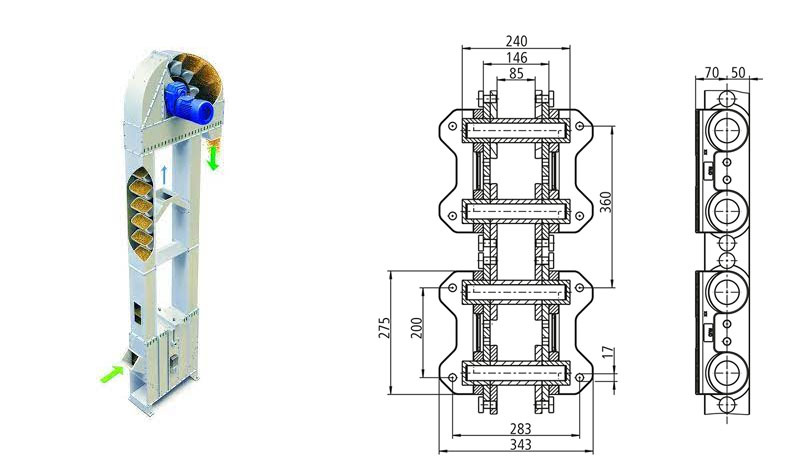

How does the Chain Type Bucket Elevator work?

The Chain Type Bucket Elevator uses a high-strength chain to drive the hopper to lift the material from the bottom to the top for unloading. The main working process is as follows:

Feeding stage: The material enters the hopper through inflow feeding to reduce extrusion and collision8.

Lifting stage: The chain drives the hopper to rise vertically, and the material is stably transported in the closed casing.

Unloading stage: After reaching the top, the material is discharged under the action of gravity or centrifugal force5.

Return stage: The empty hopper returns to the bottom along the other side and works in a cycle.

What are the applications of Chain Type Bucket Elevator?

Chain bucket elevator can be used in cement industry (lifting cement clinker, raw meal, slag, etc.), chemical industry (transporting fertilizer, plastic particles, chemical raw materials), mining industry (lifting ore, gravel, coal), grain industry (transporting wheat, corn, feed, etc.), environmental protection industry (waste treatment, biomass particle transportation).

How to choose Chain Type Bucket Elevator?

Determine the material characteristics (powder/granular/lump, abrasiveness, temperature).

Calculate the conveying capacity and lifting height (maximum 200 tons/hour, maximum 60 meters).

Select the chain type (NE plate chain is suitable for highly abrasive materials, TH ring chain is suitable for medium loads).

Consider the temperature resistance requirements (standard type ≤250℃, high temperature type can be customized).

Match the drive mode (single drive or dual drive).

TH type chain bucket elevator

TH type chain bucket elevator