Ceramic powder conveying bucket elevator

Equipment specially designed for vertical conveying of ceramic powder and other fine granular materials

| Lifting height | 3 - 45 m |

| Lifting capacity | 10 - 1200 tons/hour |

| Hopper material | Plastic, stainless steel, high manganese steel, etc. |

| Drive mode | Belt drive or chain drive |

| Applicable materials | Ceramic powder, chemical powder, cement, etc. |

| power | Customized according to conveying height and capacity |

| Sealing performance | Fully enclosed design, no leakage |

What is Ceramic Powder Conveying Bucket Elevator?

Ceramic powder conveying bucket elevator is a device specially used for vertical conveying of powdered materials such as ceramic powder. It lifts materials from low to high through a bucket fixed on a belt or chain, and is suitable for conveying scenarios that require high efficiency, closed and pollution-free. Its design focuses on preventing powder leakage and material damage, and is widely used in ceramics, chemicals, building materials and other industries.

What are the functions of Ceramic Powder Conveying Bucket Elevator?

Vertical conveying: lifts ceramic powder from low to high, and the conveying height can reach 3 meters to 45 meters.

Quantitative conveying: quantitative conveying can be achieved to ensure that the amount of material conveyed each time is consistent.

Closed conveying: adopts a fully enclosed structure to prevent powder leakage and environmental pollution.

Efficient conveying: achieves high conveying volume and high efficiency by optimizing the bucket design and operating speed.

Damage-free conveying: adopts low-speed operation and special bucket design to ensure that the ceramic powder is not damaged during the conveying process.

Ceramic Powder Conveying Bucket Elevator Application

Ceramic industry: used to convey powdered materials such as ceramic raw materials and glazes.

Chemical industry: suitable for conveying chemical powders and granular materials.

Building materials industry: used for vertical conveying of powdered materials such as cement and lime.

Food industry: suitable for conveying food-grade powdered materials such as flour and powdered sugar.

Ceramic Powder Conveying Bucket Elevator Customer Cases

| Application Scenario | Lifting Amount | Lifting Height |

| A ceramic raw material processing plant, used for continuous transportation of high-purity alumina powder to a 4-meter high mixing and stirring system | 15-20 tons/hour (powder bulk density 0.8-1.2g/cm³) | 4 meters |

| A ceramic glaze production line in Vietnam, with a ton bag unloader to automatically load materials to a 6-meter high storage bin | 8-12 tons/hour (powder moisture content <3%) | 6 meters (with automatic unloading bucket device) |

| A special ceramic factory in South Africa, used to lift fine ceramic powder (particle size <100 mesh) after screening to a 3-meter high packaging line | 1.5-2.5 cubic meters/hour (intermittent operation) | 3 meters (save space and avoid blockage of traditional spiral machines) |

How does the Ceramic Powder Conveying Bucket Elevator work?

The ceramic powder bucket elevator drives the lifting belt or chain through the motor, driving the chain or belt with the bucket to move upward. The material is lifted in the bucket, and after reaching a certain height, it is dumped out through the discharge port. During the lifting process, the material is subject to less wear in the bucket, maintaining good material properties.

What are the advantages of Ceramic Powder Conveying Bucket Elevator?

High efficiency and energy saving: adopt low-speed operation and optimized design to reduce energy consumption.

No pollution: fully enclosed structure to prevent powder leakage and environmental pollution.

Low breakage rate: special bucket design and low-speed operation to ensure material integrity.

Easy maintenance: modular design, easy to disassemble and maintain.

Strong adaptability: can be customized according to different material characteristics to meet diverse needs.

Ceramic Powder Conveying Bucket Elevator Parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

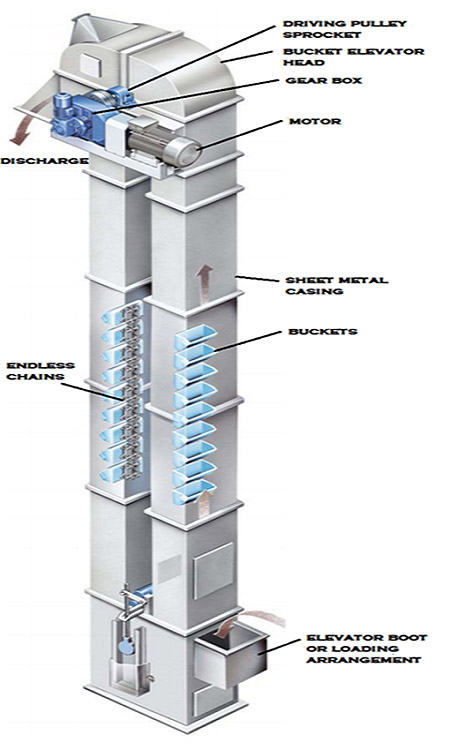

Ceramic Powder Conveying Bucket Elevator Structure

Hopper: used to load and convey materials, the material can be plastic or metal, selected according to the material characteristics

Belt or chain: as a driving component, drive the bucket to run

Drive device: including motor and reducer to provide power.

Shell: Fully enclosed structure to prevent powder leakage.

Feed port and discharge port: used for material loading and unloading respectively.

Ceramic Powder Conveying Bucket Elevator Parameters

How to select Ceramic Powder Conveying Bucket Elevator?

1. Material Properties (Key Factors for Ceramic Powder)

A. Powder Characteristics

Particle Size & Flowability:

Fine powders (e.g., alumina, zirconia) may require sealed designs to prevent dust leakage.

Coarse or abrasive powders (e.g., ceramic granules) need wear-resistant buckets & chains.

Moisture & Stickiness:

If the powder is hygroscopic (absorbs moisture), choose stainless steel construction to avoid clogging.

For sticky powders, anti-adhesion coatings or vibratory discharge may be needed.

Explosiveness & Static Sensitivity: If the powder is combustible (e.g., fine ceramic dust), select ATEX-certified explosion-proof motors.

B. Recommended Bucket Types

| Powder Type | Best Bucket Style | Reason |

| Fine, Dry Powder | Polyethylene (PE) or Stainless Steel Buckets | Prevents static buildup, easy cleaning |

| Abrasive Powder | Wear-Resistant Steel Buckets | Longer lifespan under friction |

| Sticky Powder | Perforated or Coated Buckets | Reduces material clinging |

2. Lifting Height (Vertical Conveying Distance)

| Lifting Height | Suitable Elevator Type | Notes |

| < 10m | Belt-Type (D Series) | Light-duty, cost-effective |

| 10-30m | Chain-Type (TH/NE Series) | Heavy-duty, high stability |

| > 30m | Heavy-Duty Chain (NE Series) | Reinforced structure for tall lifts |

For ceramic powders, NE or TH series are preferred due to better sealing and dust control.

Space constraints? Consider Z-type bucket elevators for horizontal + vertical movement.

3. Capacity (Throughput Requirements)

| Capacity (Ton/Hour) | Recommended Model | Motor Power (kW) |

| 1-10 T/H | D/HL Series | 2.2-7.5 kW |

| 10-50 T/H | TH/NE Series | 7.5-22 kW |

| 50+ T/H | Custom Large NE Series | 30+ kW |

Example Calculation:

If you need 20 T/H at 15m height, a NE30 model with 11 kW motor would be ideal.

4. Power & Drive System Selection

A. Motor Type

Standard Motor: For general ceramic powder (non-explosive).

Explosion-Proof Motor: Required for combustible dust (ATEX/IECEx).

Frequency Control Motor: Adjustable speed for varying loads.

B. Transmission System

Chain Drive (TH/NE Series): Best for heavy loads & high lifts.

Belt Drive (D Series): Quieter, but less durable for abrasive powders.

C. Additional Features

Dustproof Design: Critical for fine ceramic powders.

Inspection Doors: For easy maintenance.

Overload Protection: Prevents motor burnout.

Bucket Elevator

Bucket Elevator Chemical Raw Material Bucket Elevator

Chemical Raw Material Bucket Elevator