Centrifugal Bucket Elevator

| Bucket volume | 5.2~10L |

| Bucket speed | 1.25m/s |

| Motor power | 5.5~7.5KW |

| Conveying capacity | 365 cubic meters per hour |

| Height | 60m |

What is the Centrifugal Bucket Elevator?

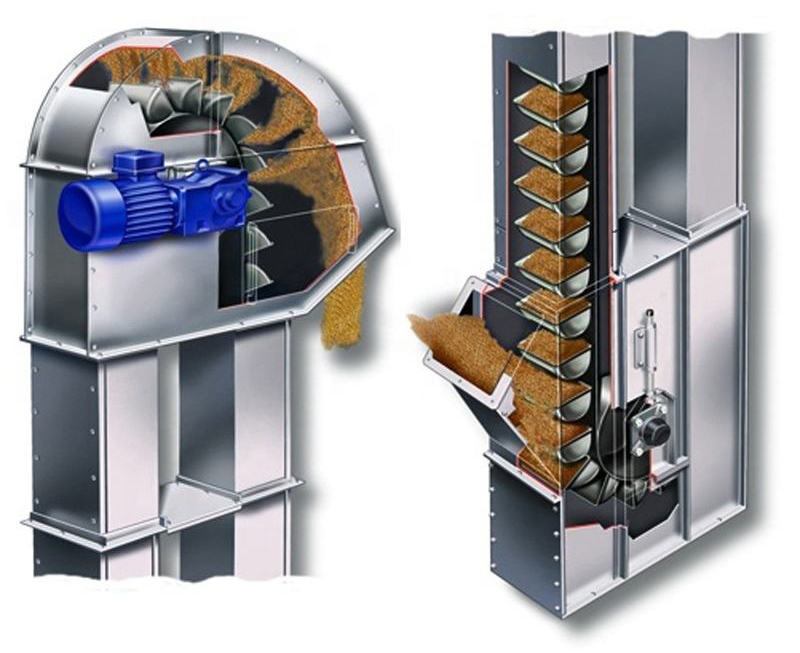

Centrifugal Bucket Elevator is a vertical conveying equipment that uses the centrifugal force to discharge the bucket. It is designed for conveying powder, granular and small block materials such as cement, coal, grain and minerals. Unlike gravity discharge elevators, centrifugal elevators use high-speed rotation to throw materials out of the bucket, ensuring higher throughput and higher efficiency, suitable for industrial applications.

What types of Centrifugal Bucket Elevator are there?

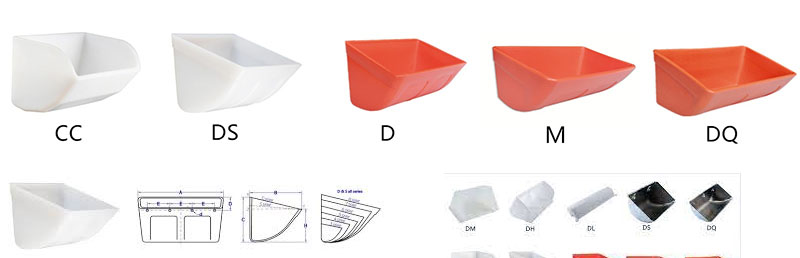

Centrifugal Bucket Elevator has deep bucket and shallow bucket, horizontal and inclined discharge modes, left drive and right drive, which can be selected according to different materials and application scenarios

By Bucket Design

S-Type (Deep Buckets) – Ideal for dry, free-flowing materials (e.g., cement, coal, grains).

Q-Type (Shallow Buckets) – Best for sticky or moist materials (e.g., wet sand, clay).

By Discharge Method

X1 (Inclined Discharge) – For controlled material flow.

X2 (Horizontal Discharge) – For direct chute feeding.

By Drive Position

Left-Side Drive – Customizable for tight plant layouts.

Right-Side Drive – Standard industrial configuration.

What are the advantages of Centrifugal Bucket Elevator?

High-Speed Operation (1.25 m/s): Maximizes throughput with centrifugal discharge.

Forged Steel Chains: Heavy-duty construction for longevity & low maintenance.

Gravity Tensioning System: Prevents slippage & ensures smooth operation.

Modular Design: Easy inspection & maintenance with multiple access doors.

Energy Efficient: Optimized motor & gearbox reduce power consumption by up to 30%

Centrifugal Bucket Elevator Parameters

| Model | TD160 | TD250 | TD315 | TD400 | ||||||||||||

| Hopper form | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd | Q | h | zD | Sd |

| Delivery volume(m3/h) | 5.4 | 9.6 | 9.6 | 16 | 12 | 22 | 23 | 35 | 17 | 30 | 25 | 40 | 24 | 46 | 41 | 66 |

| Bucket width(mm) | 160 | 250 | 315 | 400 | ||||||||||||

| Dou Rong(L) | 0.5 | 0.9 | 4.2 | 1.9 | 1.3 | 2.2 | 3.0 | 4.6 | 2 | 3.6 | 3.8 | 5.8 | 3.1 | 5.6 | 5.9 | 9.4 |

| Bucket distance(mm) | 280 | 350 | 360 | 450 | 400 | 500 | 480 | 560 | ||||||||

| Bandwidth(mm) | 200 | 300 | 400 | 500 | ||||||||||||

| Bucket speed(m/s) | 1.4 | 1.6 | 1.6 | 1.8 | ||||||||||||

| Bulk material(mm) | 25 | 35 | 45 | 55 | ||||||||||||

| Model | TD500 | TD630 | TD160 | TD250 | TD350 | TD450 | ||||||||||

| Hopper form | Q | h | zD | Sd | h | zD | Sd | Q | S | Q | S | Q | S | Q | S | |

| Delivery volume(m3/h) | 38 | 70 | 58 | 92 | 85 | 89 | 142 | 4.7 | 8 | 18 | 22 | 25 | 42 | 50 | 72 | |

| Bucket width(mm) | 500 | 630 | 160 | 250 | 350 | 450 | ||||||||||

| Dou Rong(L) | 4.8 | 9 | 9.3 | 15 | 14 | 14.6 | 23.5 | 0.65 | 1.1 | 2.6 | 3.2 | 7 | 7.8 | 14.5 | 15 | |

| Bucket distance(mm) | 500 | 625 | 710 | 300 | 400 | 500 | 640 | |||||||||

| Bandwidth(mm) | 600 | 700 | 200 | 300 | 400 | 500 | ||||||||||

| Bucket speed(m/s) | 1.8 | 2 | 1 | 1.25 | 1.25 | 1.25 | ||||||||||

| Bulk material(mm) | 60 | 70 | 25 | 35 | 45 | 55 | ||||||||||

What are the applications of Centrifugal Bucket Elevator?

Centrifugal bucket elevators are commonly used to transport fluid, small and bulk materials. They are widely used in the cement industry (clinker, raw meal, fly ash transportation), power plants (coal and biomass fuel transportation), food processing (grain, flour, sugar transportation), mining and minerals (ore, sand, gravel lifting) and chemical industry (fertilizer, plastic granules, industrial powder), etc.

Centrifugal Bucket Elevator Customer Case

A cement plant needed a high capacity elevator to transport clinker (up to 30 t/h); we supplied an HL-400 Centrifugal Bucket Elevator with deep bucket (S-type) and heat-resistant chains; increased production by 35%, reduced maintenance downtime, and the sealed design minimized dust emissions

Differences between Centrifugal Bucket Elevator and Continuous Type

| Characteristics | Centrifugal bucket elevator | Continuous bucket elevator |

| Discharging method | Using centrifugal force to discharge, the bucket has a higher running speed at the head | Using the gravity of the material to discharge, the speed of the bucket at the head is relatively low |

| Conveying speed | Higher | Low |

| Conveying volume | Relatively large | Relatively small |

| Hopper arrangement | There is a certain distance between hoppers | The hoppers are arranged closely, with almost no gaps |

| Applicable materials | Bulk materials, such as powder, granules, small blocks, etc. | Bulk and block materials, with lower requirements for material breakage |

| Drive mode | Usually single chain or belt drive | Usually double chain drive is adopted, which makes the operation more stable |

| Application scenario | Occasions requiring higher conveying speed and larger conveying volume | Occasions requiring stable conveying and low material damage rate, such as conveying fragile materials |

Centrifugal Bucket Elevator Bucket Elevator Options

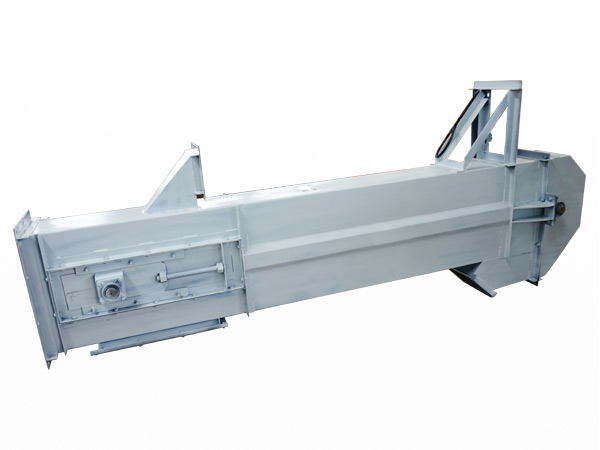

1. Machine head parts: It is assembled into one by the upper casing, the driving shaft parts, the reducer, the coupling, the motor, etc.

2. Middle case: According to the height required to be lifted, different numbers of middle case can be stacked together to meet the needs.

3. The lower part: it is composed of the bottom casing, the driven shaft part and the tensioning device. There is a door on the side of the casing that can be opened to inspect the interior such as cleaning.

4. Chain and hopper: The chain is a round steel welded ring chain, and the hopper is fixed on the joint of the chain with a nut. Bucket elevators with different heights are now equipped with corresponding number of chains, joints, and hoppers.