Cement clinker conveying bucket elevator

Used to transport cement clinker vertically, lifting cement clinker from low to high through the hopper.

Lifting height: 10-100 meters

Conveying capacity: 50-500t/h

Bucket width: 200-800 mm

Bucket speed: 0.8-2.5 m/s

Motor power: 7.5-200 kW

What is Cement clinker conveying bucket elevator?

Cement clinker conveying bucket elevator is a mechanical equipment specially used for vertical transportation of cement clinker. It lifts cement clinker from low to high through a bucket fixed on a chain or belt, and is widely used in cement plants, building materials plants and other industrial fields.

What are the applications of cement clinker conveying bucket elevator?

Cement clinker conveying bucket elevators play a crucial role in cement manufacturing and other industries that handle bulk materials. Here's a breakdown of their key applications:

Cement Manufacturing:

a. Clinker Transportation:

These elevators are primarily used to vertically transport cement clinker, a crucial intermediate product, from kilns to storage silos.

They facilitate the efficient movement of clinker within the production process.

b. Raw Material Handling:

They are also used to lift raw materials like limestone, clay, and other aggregates to crushers or storage areas.

This ensures a continuous supply of materials for cement production.

c. Finished Product Handling:

Bucket elevators assist in moving finished cement powder from mills to silos for packaging and distribution.

Other Industrial Applications:

Heavy Material Handling:

Beyond cement, these elevators are used in industries that handle heavy bulk materials like aggregates, ores, and minerals.

Bulk Storage Operations:

They are essential for transferring bulk materials to storage silos or bins in various industrial settings.

Recycling Plants:

Bucket elevators are employed in recycling facilities to elevate materials during sorting and processing.

How does the Cement Clinker Conveying Bucket Elevator work?

Cement clinker enters the hopper from the feed port, and the motor drives the hopper chain or belt to drive the hopper upward. When the hopper reaches the top, the cement clinker is discharged under the action of gravity or centrifugal force, and the cement clinker enters the next process through the discharge port.

What are the advantages of cement clinker conveying bucket elevator?

Large conveying capacity: can efficiently convey a large amount of cement clinker;

High lifting height: the lifting height can reach 40 meters, and some models can reach 80 meters;

High temperature resistance: using a special chain structure, it can convey materials with a temperature of up to 250℃;

Stable operation: reasonable structural design, stable operation, and low failure rate;

Long life: using high-strength materials, long service life.

Cement clinker conveying bucket elevator technical parameters

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

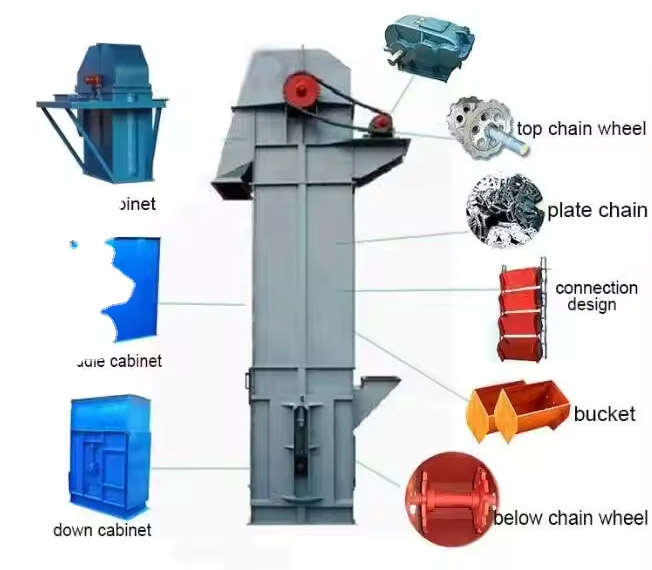

Cement clinker conveying bucket elevator structure and components

Hopper: used for loading and unloading materials;

Chain or belt: pulls the bucket to move;

Drive device: includes motor, reducer and sprocket to provide power;

Casing: sealed structure to prevent dust from spilling;

Tensioning device: adjusts the tightness of the chain or belt.

Cement clinker conveying bucket elevator case

| Application | Lifting Height | Capacity |

| Transport high-temperature cement clinker (≤250°C) from the kiln outlet to the clinker storage or cooling system | 25–40 meters (to meet the vertical transportation needs of large cement plants) | 100–800 m³/h |

| Lifting clinker from the ground to the ship loader or truck (outdoor operation) | 15–30 meters (for ship/vehicle loading height) | 50–200 m³/h (medium speed conveying, avoiding blockage). |

| Clinker lifting for small and medium-sized cement plants or concrete mixing plants | 8–15 meters (compact plant layout) | 15–50 m³/h (for intermittent production) |

How to choose cement clinker conveying bucket elevator

Conveying capacity: select the appropriate model according to production needs;

Lifting height: determine the lifting height according to the site layout;

Material characteristics: such as particle size, temperature, humidity, etc.;

Environmental requirements: such as explosion-proof, high temperature resistance and other special requirements;

Maintenance cost: select equipment that is easy to maintain and has a long life.

GTD Bucket Elevator

GTD Bucket Elevator