Case Study of Special Bucket Elevator for Dry Mortar Production Line

Dry silt mortar is a kind of granular or powdery material which is physically mixed by aggregate (such as quartz sand), inorganic cementitious material (such as cement) and additive (such as polymer) after drying and sieving, and is transported to the construction site in bags or bulk, and can be directly used after mixing with water.

In the whole dry mortar production line, a variety of equipment need to cooperate with each other, such as screening equipment, conveyor equipment, elevator equipment in the dry mortar industry has played a very important role. A few days ago, customers from Yunnan came to consult the design scheme of upgrading equipment in the whole production line.

Through the information provided by customers, we know that finished sand is lifted by bucket elevator and loaded into storage warehouse separately. Powder is pumped into their silos by bulk tankers, and additives and other bagged materials are lifted by additives lifting device and added manually to their silos. Materials in sand bin, silt bin and additive bin are discharged into their respective measuring buckets by screw conveyor in turn, and cumulative metering is carried out. When all kinds of materials are measured, the screw conveyor is started, and all kinds of materials are discharged into the bucket elevator at the same time, and the bucket elevator is discharged into the intermediate hopper. When necessary, the mixture of the intermediate hopper is discharged directly into the mixer for mixing. After a certain period of time, the finished materials are discharged and stored by the discharging port of the mixer. There is a finished product transitional bucket, which is packaged by packaging machine, or sent into finished product warehouse by screw conveyor and bucket elevator to complete a work cycle.

It can be seen that all materials in the whole dry mortar production line can not be lifted without lifting equipment. According to the information of equipment height and lifting capacity provided by customers, combined with the production situation on the spot, we recommend the bucket elevator series for customers.

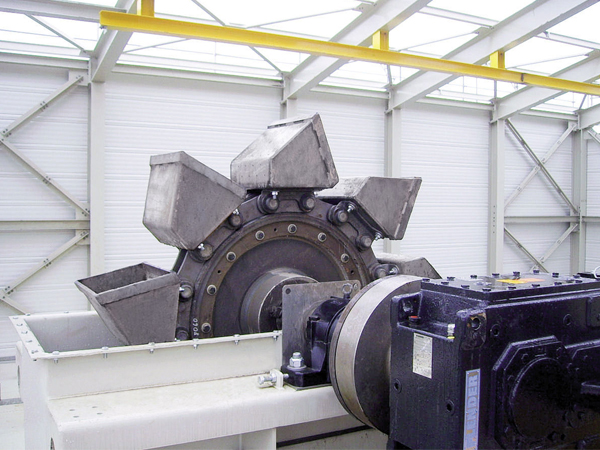

Bucket elevator has a wide range of applications, suitable for vertical lifting of various materials such as powder, granular, small block and grinding large block. It has the advantages of large conveying capacity, high lifting height, stable and reliable operation, small occupation area and long service life. Bucket elevator commonly used by us is vertical type, which can be divided into two types. It is TD belt bucket elevator, TH ring chain bucket elevator and NE plate chain bucket elevator. Bucket elevator is widely used in metallurgy, chemical industry, building materials, mining, grain and oil, plastics, medicine, food, feed and other industries.

Bucket elevator features:

1. Small driving power, large capacity of hopper-intensive layout, material elevatoring almost no return and digging phenomenon, so the ineffective power is less.

2. The lifting range is wide, and the TD bucket elevator requires fewer kinds and characteristics of materials. It can not only upgrade the general powder and small granular materials, but also upgrade the materials with bigger grinding ability. It has good sealing performance and less environmental pollution.