Bucket elevator for pharmaceutical raw materials

Designed specifically for the pharmaceutical industry, it is mainly used for efficient and hygienic vertical transportation of pharmaceutical raw materials and other fine-grained materials

| Conveying height | 3m to 90m |

| Conveying capacity | 6 to 30,000m3/h |

| Hopper capacity | 1.8L to 6.5L |

| Power supply voltage | 110V to 660V |

| Motor power | usually 1.5kW to 15kW, the specific power is determined according to the lifting height and production requirements |

| Material | Stainless steel (SUS304) or carbon steel |

| Drive mode | Chain or belt drive, the specific choice depends on the material characteristics and conveying requirements |

What is Bucket elevator for pharmaceutical raw materials?

Bucket elevator for pharmaceutical raw materials is a device used for vertical transportation of bulk materials. It is widely used in pharmaceutical, food, chemical and other industries. In the pharmaceutical industry, Bucket elevator is mainly used to transport pharmaceutical raw materials, intermediates and other materials to ensure that the materials are not contaminated or damaged during transportation and meet the requirements of GMP (Good Manufacturing Practice) 38.

What are the functions of Bucket elevator for pharmaceutical raw materials?

Vertical transportation: lift materials from low to high, suitable for multi-layer production line layout.

Dust-free transportation: adopts a fully enclosed structure to prevent dust from spilling, meeting the cleanliness requirements of the pharmaceutical industry.

Efficient and stable: suitable for continuous production, with a transportation capacity of several tons per hour.

Protect materials: reduce the breakage rate of materials during transportation through optimized design and material selection.

Automated operation: seamlessly connect with the production line, support automated production, and reduce manual intervention.

Bucket elevator for pharmaceutical raw materials Application

Pharmaceutical industry: used to transport pharmaceutical raw materials, intermediates, excipients, etc., to ensure that the materials meet GMP standards.

Food industry: suitable for conveying granular and powdered food raw materials, such as candy, nuts, etc.

Chemical industry: used to transport chemical raw materials, such as powders and granules.

Bucket elevator for pharmaceutical raw materials customer case

| Application Scenario | Amount of improvement | Raise height |

| A leading pharmaceutical manufacturer in Germany requires a dust-free, GMP-compliant bucket elevator to transport high-value API powders from ground-level mixing to a 10-meter-high encapsulation line. | 8–10 tons/hour | 10 meters |

| A US-based pharma plant needed a hygienic, low-breakage elevator to move MCC powder from storage silos to tablet press feeders. | 5–7 tons/hour | 5 meters |

| A sterile drug production facility in India requires an aseptic, fully enclosed bucket elevator to transport antibiotic granules between floors | 6–8 tons/hour | 7 meters |

How does the Bucket Elevator for Pharmaceutical Raw Materials work?

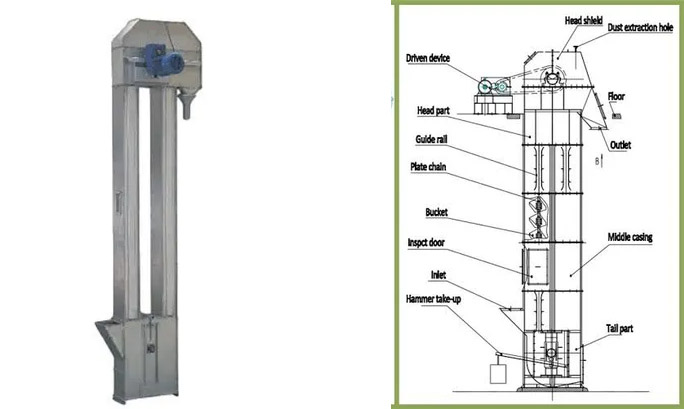

The Bucket Elevator lifts pharmaceutical raw materials from the bottom to the top through a bucket fixed on a belt or chain. The pharmaceutical raw materials are discharged at the top by centrifugal force or gravity, completing the vertical conveying process. The equipment usually consists of a drive device, a transmission roller, a tensioning roller, a hopper and a casing.

What are the characteristics of Bucket elevator for pharmaceutical raw materials?

Fully enclosed structure: prevents dust leakage and meets cleanliness requirements.

Multiple material options: The hopper and the body can be made of stainless steel (SUS304) or ABS materials, suitable for different material characteristics.

High efficiency and energy saving: low noise and low energy consumption design, suitable for continuous production.

Flexible configuration: supports single-point or multi-point unloading, which can be customized according to customer needs.

Bucket elevator for pharmaceutical raw materials Specifications

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Delivery volume m³/h | Normal type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Upgraded | - | - | - | - | - | - | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Bucket | Bucket width mm | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Bucket capacity L | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Bucket distance mm | Normal type | 500 | 512 | 688 | ||||||||||||||

| Upgraded | - | 384 | 516 | |||||||||||||||

| Chain | Round steel (diameter×pitch)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Number of rings | Normal type | 9 | 7 | 7 | ||||||||||||||

| Upgraded | - | 5 | 5 | |||||||||||||||

| Bucket running speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Main sprocket pitch diameter mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed r/min | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| Particle size mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||

Bucket elevator for pharmaceutical raw materials structure composition

Hopper: used to carry materials, the material can be ABS, PP or stainless steel.

Transmission device: including drive roller, tensioning roller and belt/chain.

Casing: fully enclosed design to prevent dust leakage.

Control system: supports automatic operation and can be integrated into the production line.

How to select Bucket elevator for pharmaceutical raw materials?

1. Material Properties (Key Factors for Pharma Raw Materials)

A. Powder/Granule Characteristics

Flowability & Stickiness:

Free-flowing powders (e.g., lactose, MCC) work well with centrifugal discharge elevators.

Sticky or cohesive materials (e.g., wet granules) may require vibratory-assisted discharge.

Abrasiveness:

Highly abrasive materials (e.g., some APIs) need wear-resistant stainless steel (316L) buckets & chains.

Hygroscopicity & Sensitivity:

Moisture-sensitive powders (e.g., hygroscopic excipients) require nitrogen-purged or desiccant-dried enclosures.

Explosibility (ATEX Compliance):

Combustible dust (e.g., fine APIs) needs explosion-proof motors & grounding systems.

B. Material-Safe Construction

| Material Type | Recommended Bucket/Chute Material |

| Non-reactive powders | 304 Stainless Steel |

| Corrosive/acidic APIs | 316L Stainless Steel (electropolished) |

| Ultra-clean applications | Polypropylene (PP) or FDA-grade UHMWPE |

2. Lifting Capacity (Throughput Requirements)

| Capacity (kg/h) | Recommended Elevator Type | Motor Power (kW) |

| < 500 kg/h | Small Z-Type or Belt Elevator | 0.75–2.2 kW |

| 500–5,000 kg/h | NE/TH Chain Elevator | 3.7–15 kW |

| > 5,000 kg/h | Heavy-duty NE Series | 18.5–30 kW |

3. Lifting Height (Vertical Conveying Distance)

| Lifting Height | Best Elevator Type | Notes |

| < 5m | Z-Type or Belt Elevator | Compact, ideal for inter-floor transfers |

| 5–20m | NE/TH Chain Elevator | Most common for pharma plants |

| > 20m | Custom Heavy-Duty NE | Requires reinforced structure |

Bucket elevator for pharmaceutical raw materials price

The price of Bucket elevator for pharmaceutical raw materials varies depending on specifications, materials and customization requirements:

Standard model: about US$2,000 to US$20,000 per unit.

High-end customized model: up to US$200,000 per unit.

The specific price needs to be quoted according to customer requirements (such as conveying height, production capacity, materials, etc.)

Chemical Raw Material Bucket Elevator

Chemical Raw Material Bucket Elevator