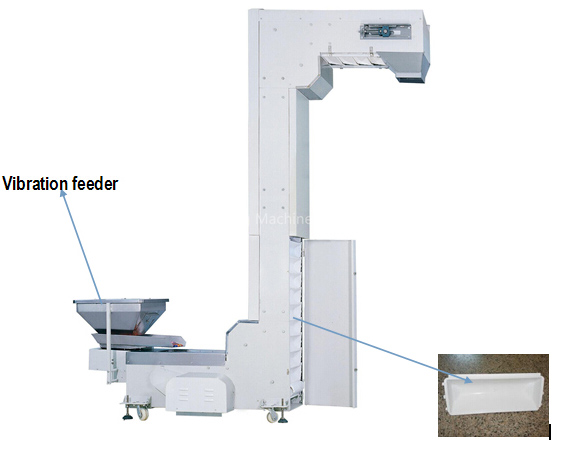

Bucket Elevator With Hopper Feeder

Precise feeding to achieve continuous and stable material lifting

| Machine Frame | Carbon steel, 304 stainless steel |

| Bucket Materials | ABS/PP/304 stainless steel |

| Bucket Volume | 1.0/1.8/3.8/6.5L |

| Height | 3896mm or customized. |

| Capacity | 2-12m³/h |

What is Bucket Elevator With Hopper Feeder?

Bucket Elevator With Hopper Feeder is a highly efficient vertical conveying equipment, widely used in food processing, agriculture, chemical, pharmaceutical and other industries. Its design combines the advantages of hopper and bucket elevator to achieve continuous, smooth and pollution-free vertical conveying of materials.

The product is continuously and very gently fed into the bucket elevator by a vibrating feeder, the edges of the buckets overlap each other at the entrance section, so spillage is prevented, the bucket is always in the conveyor belt due to its pivotal mounting in the chain Hold their horizontal position until they finally reach the outlet, which can be equipped with multiple inlets and outlets. Ingresses can work concurrently, while outlets use singular, which means only one outlet is temporarily active.

What are the types of Bucket Elevator With Hopper Feeder?

Bucket Elevator With Hopper Feeder has continuous, intermittent, chain, belt, etc., which can be selected according to different application requirements.

Continuous bucket elevator: suitable for occasions where continuous conveying is required, with high lifting efficiency and suitable for mass production.

Intermittent bucket elevator: suitable for occasions with high conveying accuracy requirements, and can achieve precise control.

Chain bucket elevator: uses chain as a transmission device, suitable for conveying powder, granular and small block materials.

Belt bucket elevator: uses rubber or metal belt as a transmission device, suitable for occasions with large conveying volume and stable requirements.

What are the advantages of Bucket Elevator With Hopper Feeder?

Efficient conveying: Combined with the design of hopper and bucket elevator, continuous and smooth material conveying is achieved to improve production efficiency.

Multiple feeding methods: Supports multiple feeding methods such as vibrating feeder and rotary valve to adapt to different material characteristics.

Prevent material loss: Reasonable hopper design prevents material from overflowing or scattering during transportation, reducing waste.

Easy to maintain: Simple structure, easy to disassemble and clean, reducing maintenance costs.

How does Bucket Elevator With Hopper Feeder work?

The working principle of Bucket Elevator With Hopper Feeder is as follows: the material enters the bottom of the elevator through the hopper, and the bucket of the bucket elevator, driven by the transmission device, lifts the material from the bottom to the top. At the top, the bucket turns over and discharges the material into the designated equipment or container. The whole process is continuous and smooth, and is suitable for vertical transportation of a variety of materials.

Bucket Elevator With Hopper Feeder Parameters

| Bucket volume | Bucket material | No.s discharge port | Capacity | Power |

| 1L | PP/ASB/SS304/Carbon steel | single | 1-3^m/h | 0.75kw |

| 1.8L | 4-6^m/h | 0.75kw | ||

| 3.8L | muti-discharge port | 6.5-8^m/h | 1.5kw | |

| 6.5L | 5.5-12^m/h | 2.2kw |

What are the applications of Bucket Elevator With Hopper Feeder?

Bucket elevator with hopper feeder is ideal for a variety of free-flowing products in the food, agriculture, pharmaceutical, cosmetic, chemical industries, such as snack foods, frozen foods, vegetables, fruits, confectionery, chemicals, and other pellets.

Bucket Elevator With Hopper Feeder Customer Case

We have provided Bucket Elevator With Hopper Feeder solutions to many companies, helping customers improve production efficiency and reduce costs. For example:

Food processing plants: Through customized bucket elevators, efficient transportation of nuts is achieved, improving production efficiency.

Agricultural enterprises: Using our equipment, continuous transportation of grains is achieved, reducing labor costs.

Chemical companies: Through our solutions, pollution-free transportation of powdered raw materials is achieved, improving product quality.

Stainless Steel Bucket Elevator

Stainless Steel Bucket Elevator